Rewinding and Vacuum Impregnation

Electric Motor Rewind And Overhaul Services

- Home

- Services

- Workshop Repairs

- Rewinding and Vacuum Impregnation

Brochure

Download our document to see specific data of the service and how we work.

HOW CAN WE HELP YOU?

Talk or write to our experts to find your best solution.

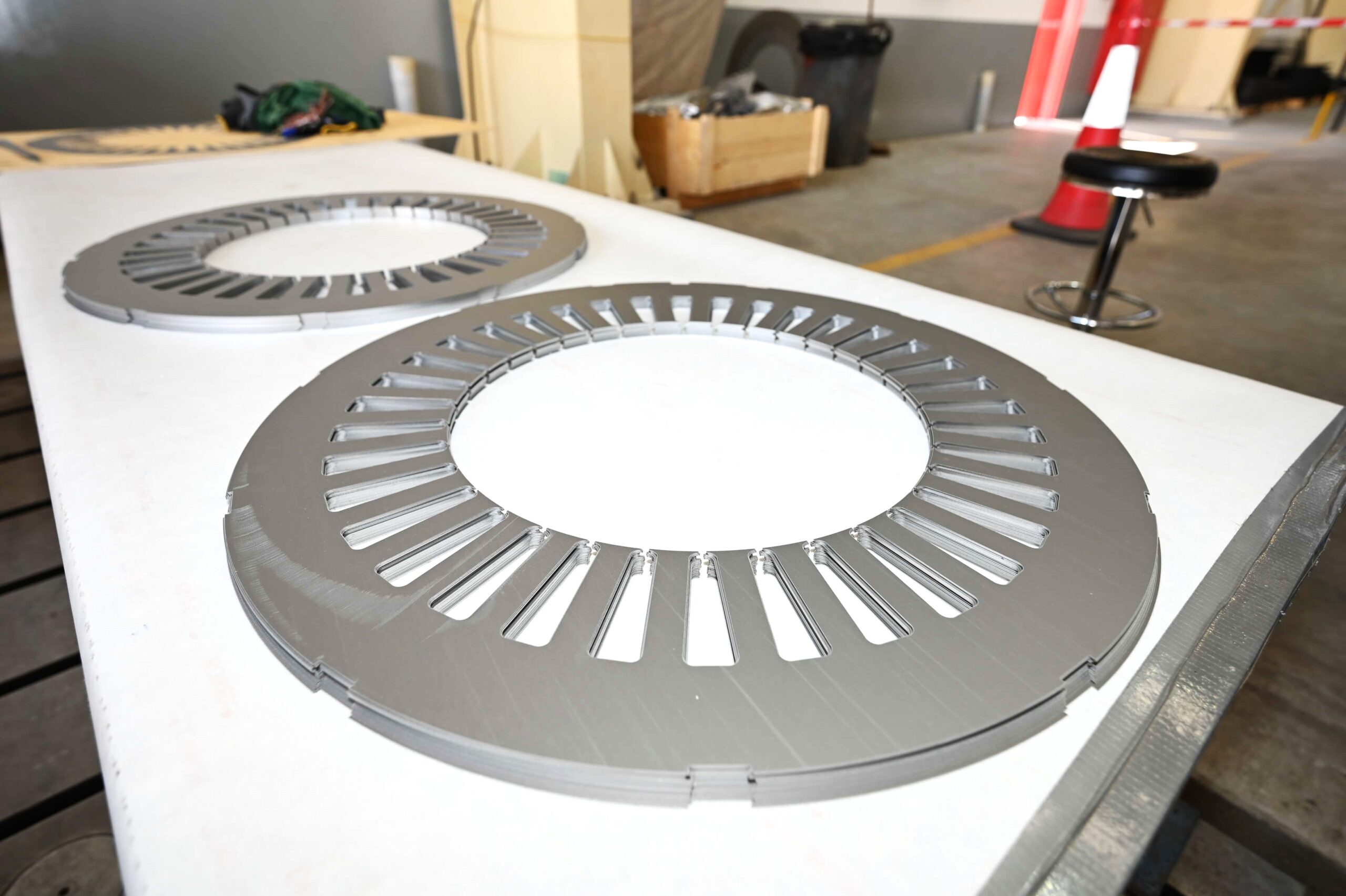

Intersel started out in 1986 as a motor and generator repair facility, so motor rewinding is part of our company's DNA. Our in-shop rewinding capabilities include (but are not limited to):

- Rewinding of AC and DC motors (Any make, standard, or custom build).

- Rewinding and testing of the small, medium, and large motors.

- Rewinding of motors ranging from fractional horsepower to 6,000 horsepower.

- Rewinding of motors from low voltages to 13.8 kV.

- Rewinding of Ex Motors.

Our motor rewinding process is augmented with our extensive testing, which ensures that the rewound motor offers exceptional performance, closer to or even surpassing the previous operational efficiency. We can reverse-engineer the winding patterns and even enhance them for current operational needs, for obsolete and custom-built motors. We also offer multiple insulation solutions for the new winding, including vacuum pressure impregnation, for superior results.

There are several benefits of choosing a premium rotating equipment service company like Intersel for your motor rewinding jobs, even if you have in-house facilities for rewinding. The most prominent ones include:

Best Practices: Our certified technicians and engineers follow the best industry practices for motor rewinding. From careful stripping of the old winding to insulation, we adhere to the best standard for every step of the job to ensure that the final results surpass expectations.

Enhancements: High-quality winding, insulation material, and newer insulation techniques like vacuum impregnation can enhance the baseline performance, efficiency, life, and mechanical and electrical configuration of older motors.

Additional Services: Motor rewinding is one of our many areas of expertise. We can handle a much larger scope of motor repair, which may include testing and repairing the core.

Faster Turn-Around: As an OEM alternative, we offer more than just "as-new" rewinding. We also offer a faster turn-around, so the operational pause/break due to the absence of motors is minimal.

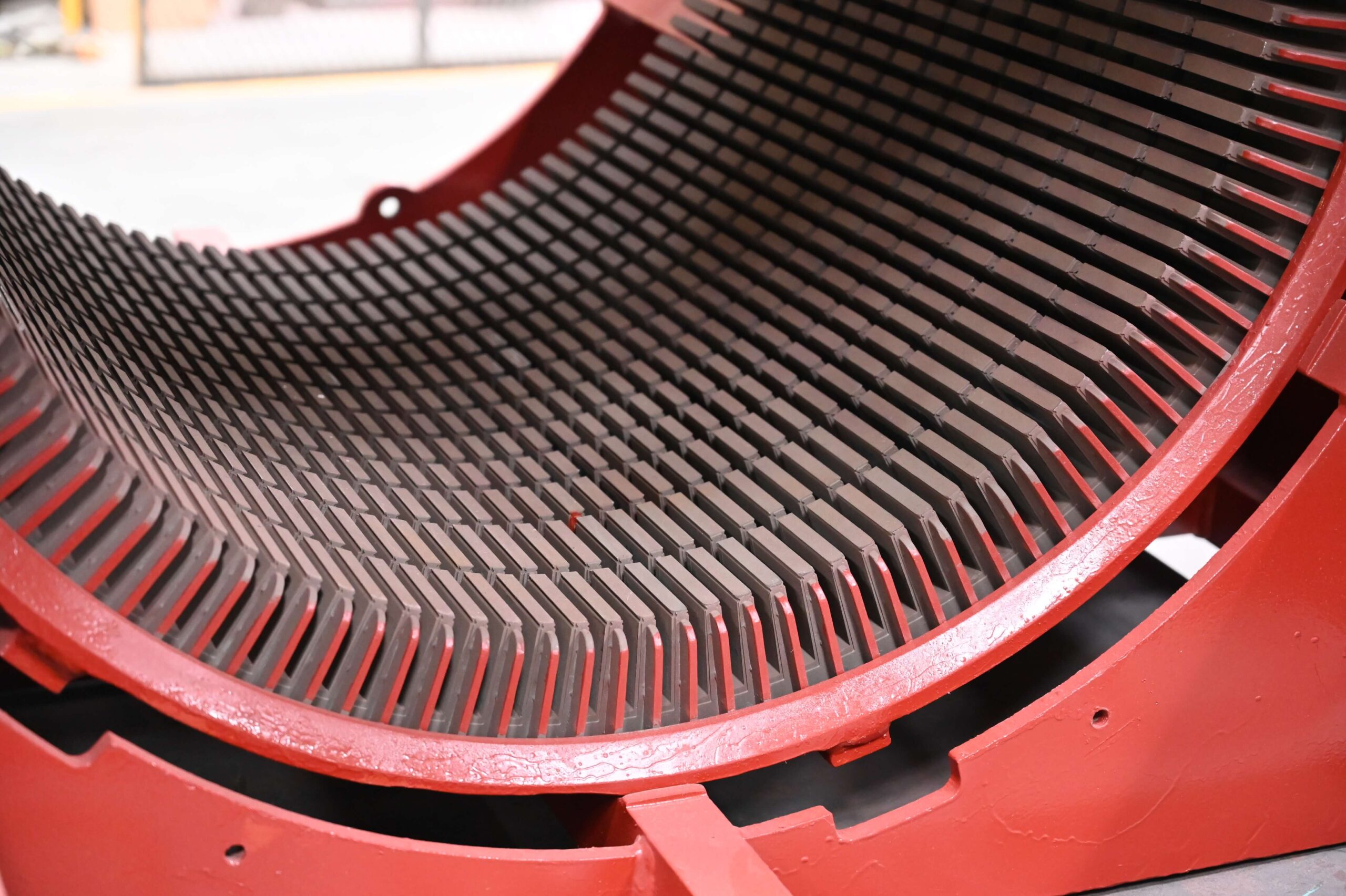

We offer rewinding services for a wide variety of generator makes and sizes. We can provide rewinding services for smaller units to generators as large as 200 MW. The largest in-shop generator rewinding job we have completed so far was for a 39,540 kVA Brush turbogenerator. Our generator rewinding services have all the benefits that set our motor rewinding services apart from our peers and competitors. Our generator testing services include the following:

- Stator Wedge Tightness Assessment

- Natural Frequency Test

- ELCID

- RSO

This allows us to convey a more comprehensive performance report to our clients after the rewinding, including a thorough assessment of the core.

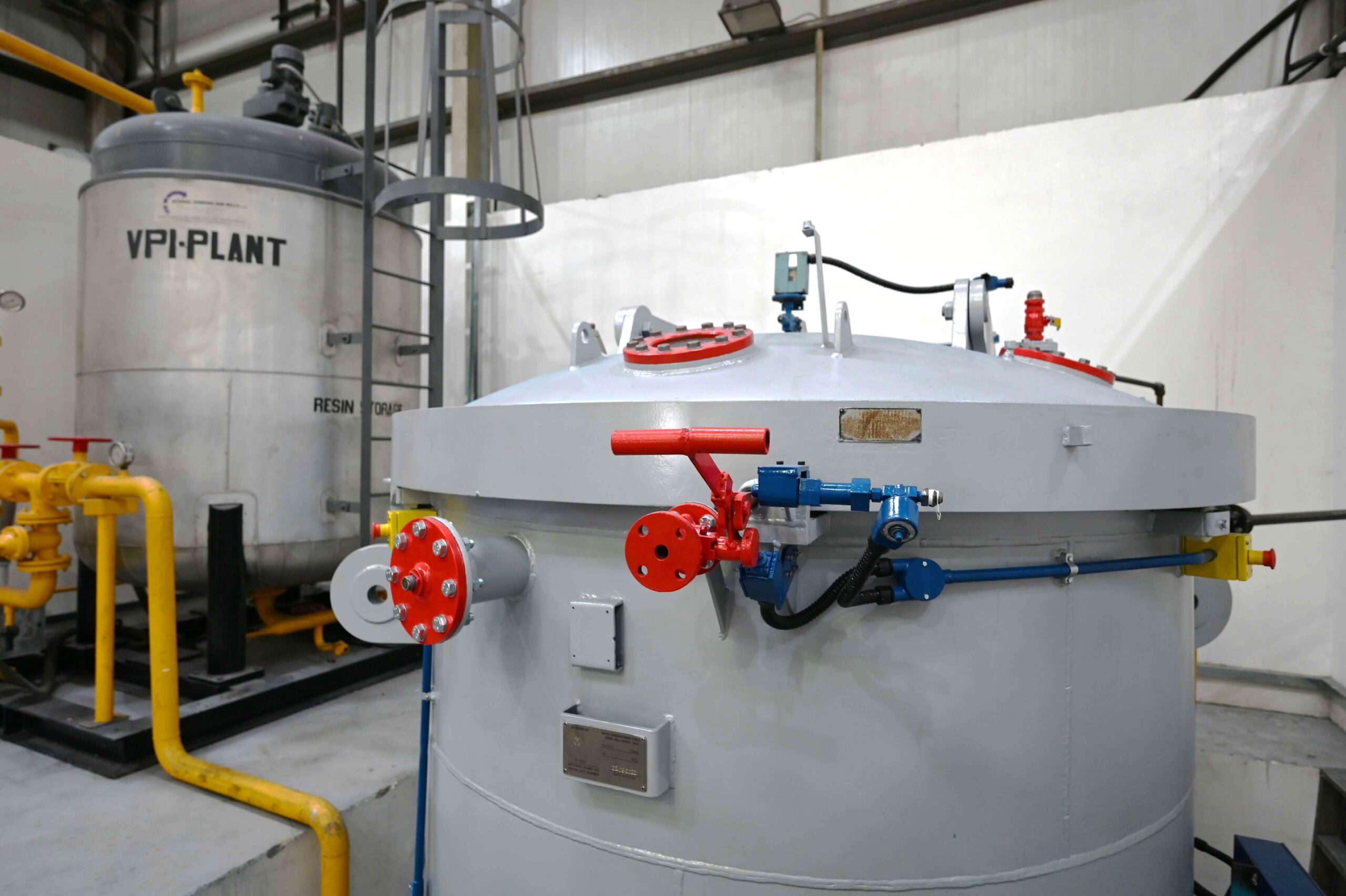

Vacuum Pressure Impregnation, or simply vacuum impregnation, can offer improved mechanical and electrical characteristics to a wide variety of industrial equipment – from motor windings to porous machine parts.

Metal castings and powdered metal parts are vulnerable to “porosity,” i.e., which is simply defined as void space within a material. This porosity allows the material to absorb, which for machine parts that may have fluid exposure, results in the formation of leak paths.

For rotating equipment like motors and generators, the typical winding insulation method has been the “dip and bake." The motor winding is dipped and baked (usually twice) to install a layer of insulation over the winding, with the additional benefit of mechanical rigidity. But even though the winding is soaked in resin or varnish, it usually doesn’t penetrate the layers between the windings.

Vacuum impregnation can solve both of these problems.

The vacuum impregnation process is similar, whether it's for machine parts or winding. The main idea is to draw out the air from leak paths and the space between the windings, so when it’s soaked in resin, it reaches everywhere. It seals up the void in metal-cast machine parts and covers the gap between the windings with resins.

It’s a four-step process:

- Rotor/stator or the porous material that needs to be vacuum sealed is inserted in the vacuum chamber where negative pressure/vacuum draws out any trapped air.

- The chamber is filled with resin to soak what is inside. Pressure may be manipulated to push the resin deeper in.

- The chamber is drained.

- The coated/soaked equipment is cured to set the resin.

Intersel has a vacuum chamber that is 1.7 m in diameter and 2 m deep. That's enough to accommodate a decent range of medium and large motors and generators.

Vacuum impregnation may not always be the most pragmatic solution, especially in favor of alternatives like B-Stage Coils, especially for large motors. But when it is a viable option, there are several benefits to choosing it.

- Enhanced mechanical strengths and reduced coil vibrations.

- Better dielectric strength.

- Improved heat dissipation.

Vacuum impregnation improves the performance and increases the life of motor and generator windings.

Industries Serviced

DELIVERING INNOVATION

Cutting Edge Engineering Solutions Since 1986

We are focused on building a long-term, sustainable business.