Brochure

Download our document to see specific data of the service and how we work.

HOW CAN WE HELP YOU?

Talk or write to our experts to find your best solution.

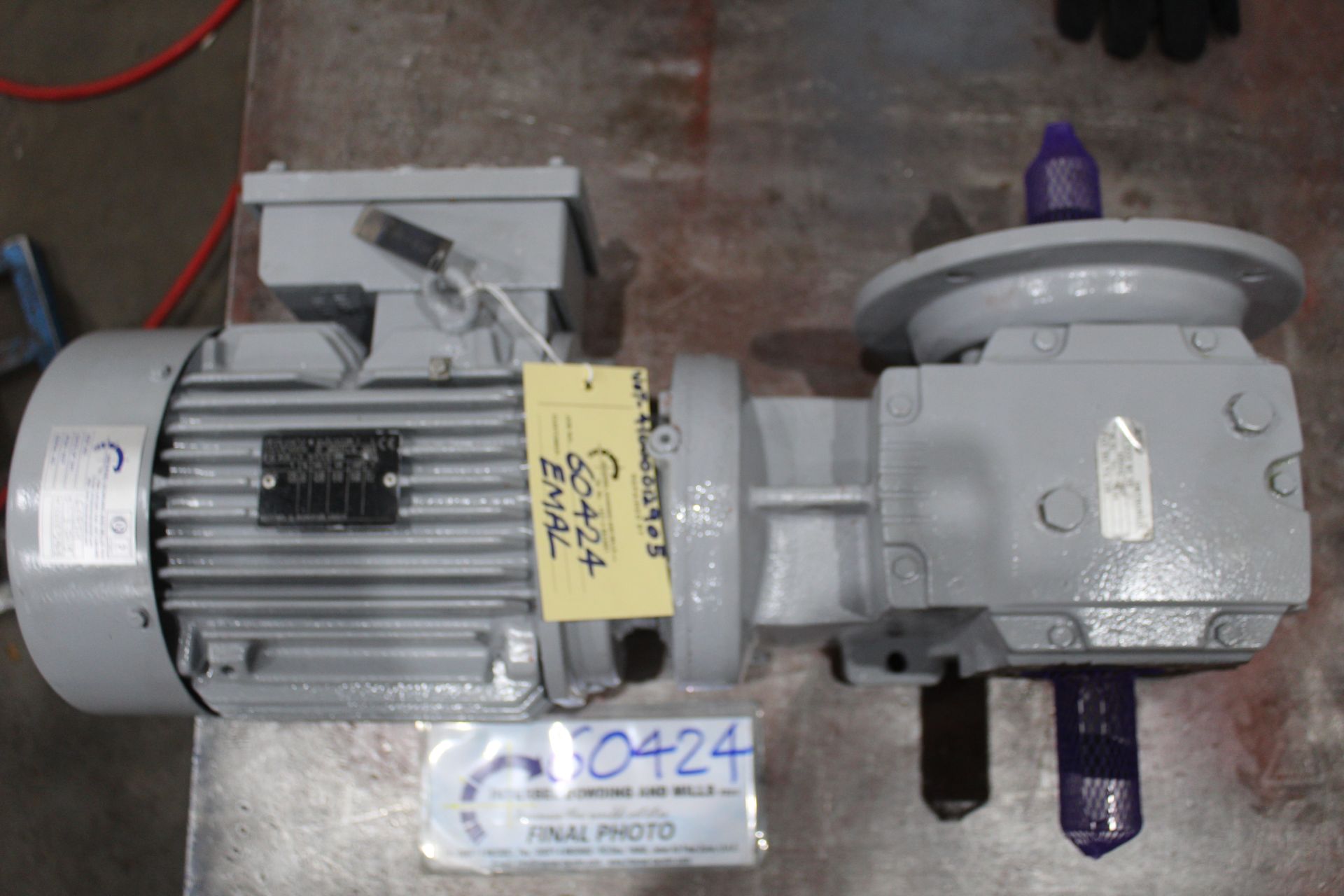

Gear Boxes

As the largest rotating equipment service provider in the Middle East, Intersel is equipped to offer complete repair, overhauling, and housing reclaiming services for gearboxes up to 80 tons in weight. We also offer replacement and repair services for gear shafts up to 2,500 mm.

Our engineers and technicians are trained and experienced to provide the services for virtually all industrial gearbox types installed in a variety of operational configurations. This includes:

- Different gearbox stages (from single-stage to multi-stage).

- Different gearbox constructions/structures, like helical (coaxial, bevel), worm reduction, and planetary.

We are well-versed in most of the problems that may arise in a gearbox operating in a specific environment. This includes misalignment arising from intrinsic (thermal expansion) or external issues (improper installation or mounting). We also guide the client’s staff on proper lubrication and cleaning practices for each gearbox to prevent frequent problems and prolong the life of the gearbox. We can also check for (and rectify) thermal instability in a gearbox when it’s still operating.

Intersel Gearbox Services

Intersel is equipped to meet the gearbox repair and overhauling needs of virtually all the major industries in the Middle East. Our primary services include:

From housing and shaft reclaiming to complete shaft replacement, we offer complete mechanical repair services for gearboxes of any make and model (standard or custom). To execute the necessary repairs, the gearboxes are disassembled up to the extent necessary to access the damaged part(s). We catalog all the repairs and replacements necessary to revert the gearbox to its original operating condition to convey to the client, so they can make an educated decision. The repairs are executed following both OEM guidelines and best industry practices to ensure that the gearbox is restored for a relatively long service life.

The gearbox overhauling services are more thorough compared to the repair services. The gearbox is completely disassembled, and an inspection is carried out before and after the disassembly (and cleaning) to identify the full scope of operational wear and damage. We replaced all the damaged and worn seals, and all the components are lubed following OEM directions.

The gearboxes are extensively tested after the reassembly before they are installed at the original site to ensure they are ready to perform as per their operational needs.

The Intersel Advantage

- We offer a generous warranty for every gearbox repair and overhaul we complete for our clients. It’s a reflection of our quality of work and useful information for clients predicting preventive maintenance shutdowns.

- Every industry has different gearbox requirements. The oil and gas industry requires rig and top drive gearboxes (among others) for upstream and high-speed gearboxes for mid and downstream operations. Wastewater treatment might require underwater gearboxes, heavy-duty and corrosion-resistant. From its housing and seals to gear material and construction, there is a substantial variety of gearboxes based on their industrial applications, and our extensive experience allows us to cater to virtually all of them.

- Our on-site capabilities, which are a valid option for several gearbox repairs and overhauling jobs, offer a significant benefit to clients with mission-critical gearboxes out of commission.

- Our reverse-engineering capabilities allow us to offer complete repair and overhauling services for legacy gearboxes or custom designs with no OEM designs available.

Industries Serviced

DELIVERING INNOVATION

Cutting Edge Engineering Solutions Since 1986

We are focused on building a long-term, sustainable business.