Mechanical Repair & Machining

Electric Motor Rewind And Overhaul Services

- Home

- Services

- Mechanical Services

- Mechanical Repair & Machining

Brochure

Download our document to see specific data of the service and how we work.

HOW CAN WE HELP YOU?

Talk or write to our experts to find your best solution.

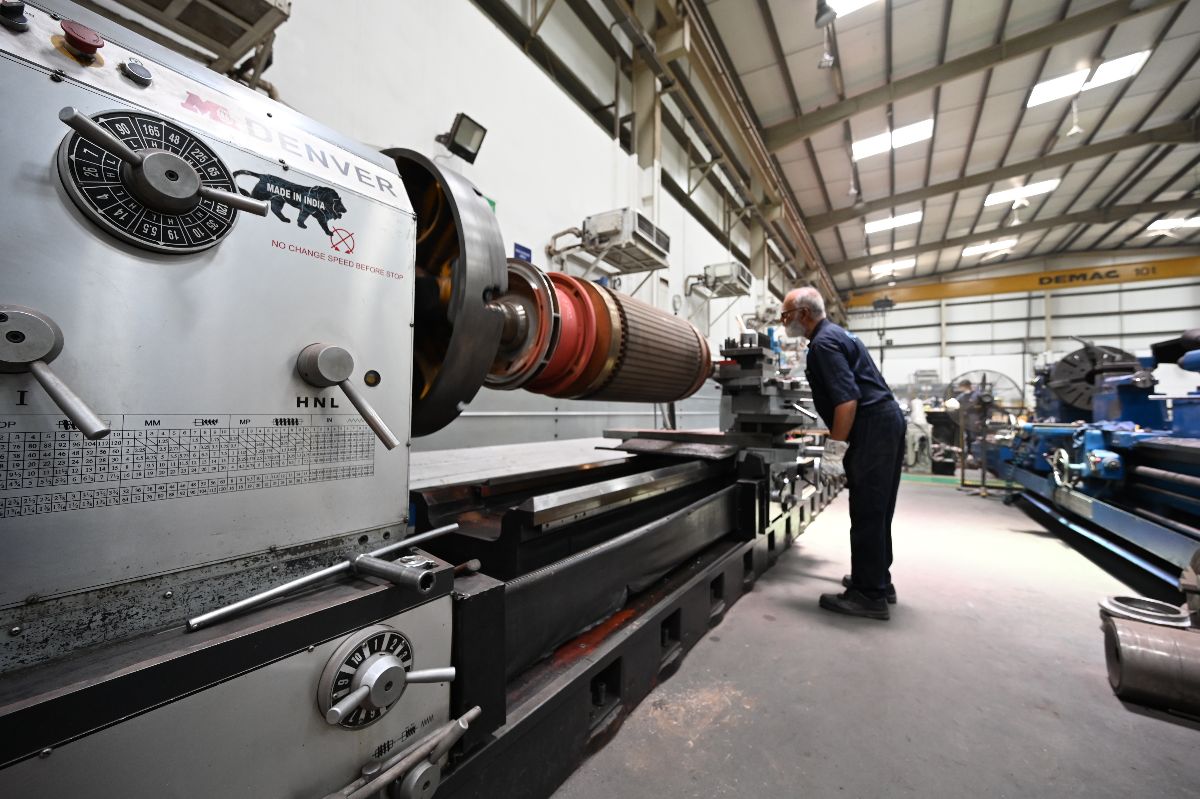

Mechanical Repair & Machining

As a leader in the rotating equipment service industry in the Middle East, Intersel offers comprehensive mechanical repair services for a wide range of rotating and other equipment. Our certified technicians and engineers can provide various mechanical repair services on-site using our mobile workshops. And the range of mechanical repairs we can offer in-shop is significantly more substantial.

The list of equipment we offer mechanical repair services for includes (but is not limited to) the following:

Intersel offers complete mechanical repairs for almost all LV, MV, and HV motors (up to 13.8 kV). From AC/DC and servo motors to purpose-built Ex motors, we offer quality repair services for standard and custom-made motors from a variety of OEMs. We offer the following mechanical repairs for motors:

- Rotor re-barring.

- Shaft replacement.

- Horizontal balancing.

- Housing replacement.

- Rotor and stator lamination replacement.

- Housing and Journal reclaiming.

- Cooling system repairs.

- Replacement manufacturing (reverse engineering).

We offer complete mechanical repairs for turbo generators of up to 200 MW. Our comprehensive testing capabilities facilitate stator core and other repairs capable of achieving or surpassing the original performance levels. Our mechanical repairs for generators include:

- Lamination replacement (Main stator, Main rotating fields, Exciter, Exciter stator).

- Amortisseur winding re-barring.

- Shaft replacement.

- Horizontal balancing.

- Housing replacement.

- Housing and Journal reclaiming.

- Cooling system repairs.

- Replacement manufacturing (reverse engineering).

Intersel’s technicians and engineers are experienced in dealing with a wide range of fan/blower mechanical repair scenarios. From worn bearings to deformed blades, we are capable of performing a wide range of mechanical repairs, including:

- Rotor re-barring.

- Shaft replacement.

- Horizontal balancing.

- Housing replacement.

- Rotor and stator lamination replacement.

- Housing and Journal reclaiming.

- Replacement fan manufacturing (reverse engineering).

Our pump repair process starts with a thorough inspection to determine the cause of a pump’s failure or performance deterioration. This assessment allows for comprehensive mechanical repairs focusing on more than just the damaged parts and potentially forestalling future mechanical damages for an extended period. Our pump repair services (mechanical) cover:

- Impeller reclaiming.

- Shaft replacement.

- Horizontal balancing.

- Housing replacement.

- Housing and Journal reclaiming.

A thorough understanding of unique wear and tear patterns in gears and simple to complex gearbox failure scenarios makes Intersel’s team distinctively qualified for the mechanical repairs of various industrial gearboxes. The two core mechanical repair services we offer for gearboxes are:

- Housing reclaiming.

- Shaft reclaiming and replacement.

A bad seal, chipped or loose bearings, and excessive pitting in the magnet assembly are just some of the problems your eddy current brakes might face. Our comprehensive mechanical repair capabilities include:

- Drum replacement.

- Magnet machining.

- Magnet welding.

- Magnet rewinding.

- Shaft reclaiming and replacement.

- Housing and Journal reclaiming.

Our 9,500+ square meter workshop, cutting-edge tools, and an experienced and well-equipped team of certified technicians and engineers allow us to handle complicated repairs while maintaining or improving the default performance specifications. Our mechanical repair process is augmented by the testing capabilities that help us identify potential points of failure, excessive wear and tear, misaligned forces (which may prematurely damage equipment), etc. Custom fabrication and reverse engineering capabilities let us circumvent problems like unavailability or late delivery of repair parts.

Intersel Machining Services

Intersel’s machining capabilities are supported by the following:

3 Lathe Machines – Capable of handling shafts up to six meters in length and 2.5 meters in diameter, weighing 25 tons.

Multiple Cranes – Maximum lifting capacity of 80 tons.

Dynamic Balancing – Maximum weight up to 12 tons and RPMs between 210 and 1680.

Horizontal and Vertical Boring Mills

Horizontal and Vertical Presses

CNC

Our machining capabilities allow us to offer an extensive suite of mechanical repair services for motors, generators, and other rotating equipment, but it’s not limited exclusively to rotating parts. We also fabricate housings, bases, supports, and other parts for our clients from various industries, many of which require custom parts for custom rotating equipment or to accommodate standard equipment in unconventional settings.

Apart from machining parts for the repair jobs we undertake, we also fabricate a variety of parts for our clients if:

- The original/OEM parts are no longer available in the market.

- They require a custom part for installation.

- Original parts are available but too expensive.

- The OEM lead time or delivery time for a custom part is unfeasible for the client.

- Retrofitting equipment requires unique parts built to client specifications.

Our machining services cover most of the essentials, including (but not limited to) milling, boring, turning, slotting, grinding, and pressing. From machining legacy parts to components that are designed to change the original performance parameters of the equipment, our experts can handle almost all machining requests from our clients.

Intersel’s three and a half decades in the rotating equipment service business catering to a diverse range of industries has resulted in machining knowledge, expertise, and skillset that sets us apart. Our capabilities are also enhanced by a pursuit of the latest machining technologies and tools and following the best industry practices.

Industries We Serve

We offer mechanical repairs and machining services to multiple industries. This includes:

- Power Generation

- Oil and Gas

- Water and Wastewater

- Metal and Steel

- Cement Manufacturing

- Petrochemical

- Marine

These and the other industries Intersel cater to have characteristic mechanical repair and machining requirements. Understanding the operations, process flow, and unique challenges associated with each industry allows Intersel to maintain high service quality.

Industries Serviced

DELIVERING INNOVATION

Cutting Edge Engineering Solutions Since 1986

We are focused on building a long-term, sustainable business.