Predictive & Preventive Maintenance

Electric Motor Rewind And Overhaul Services

- Home

- Services

- Field Services

- Predictive & Preventive Maintenance

Brochure

Download our document to see specific data of the service and how we work.

HOW CAN WE HELP YOU?

Talk or write to our experts to find your best solution.

Predictive & Preventive Maintenance

With over three decades in the field of rotating equipment repair and maintenance, Intersel has become a trusted predictive and preventative maintenance partner for hundreds of organizations.

Preventive maintenance, especially if it follows a practical schedule, has the potential to forestall many motor/generator failures and large-scale operational failures. A comprehensive approach to preventive maintenance, which follows both OEM recommendations and best industry practices, can also prolong the life of your rotating (and other) equipment, which in turn keeps the operational costs down.

Predictive maintenance, whether in conjunction with preventive maintenance or as its alternative, offers an even better way to keep your motors and generators safer. Constant monitoring and the right tests make it possible to predict (quite accurately) when equipment might need maintenance. This offers a significant improvement over preventive maintenance that follows a schedule instead of tracking the condition of the equipment and has a higher chance of preventing potential equipment failure and abnormal wear-and-tear.

The cost savings from predictive maintenance is two-fold:

- Like preventive maintenance, it prolongs equipment’s life and prevents (to an extent) total equipment failure/breakdown.

- Unlike preventive maintenance, which occurs on a predetermined schedule whether or not the equipment needs it, predictive maintenance is only performed as needed. This is the optimal approach from a cost perspective and may also reduce the frequency of small and large-scale shutdowns required for maintenance.

Intersel Predictive and Preventive Maintenance Services

Intersel uses state-of-the-art testing procedures for predictive maintenance and offers a wide variety of preventive and predictive maintenance services. The tests for motors and generators are both online and offline in nature. Intersel also offers predictive maintenance services for transformers.

- Vibration Spectrum Analysis

- Acoustic Emission Analysis

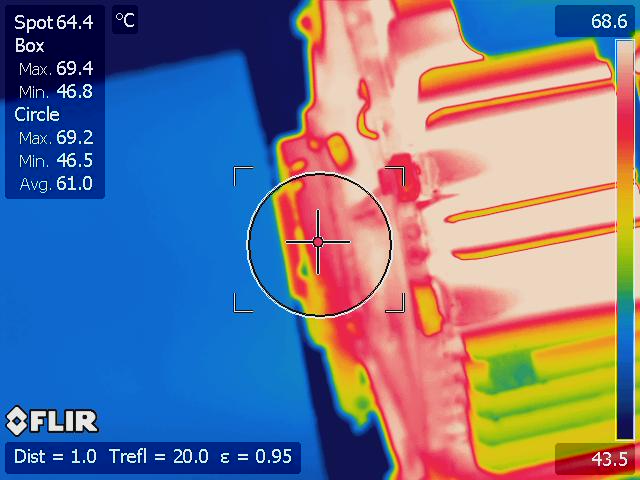

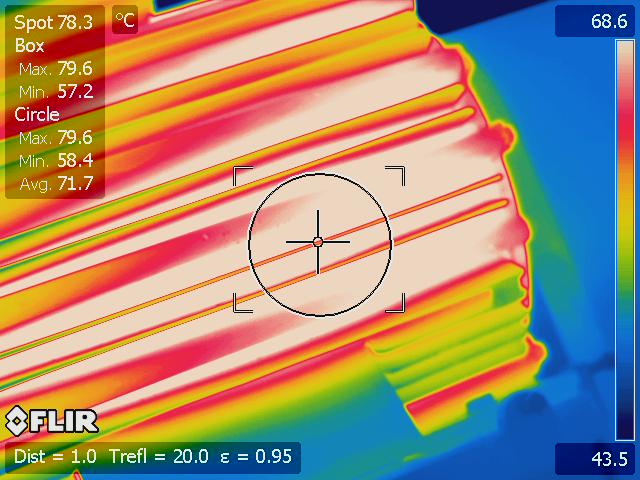

- Infrared Thermography

- On-Site Rotor Balancing

- Tan Delta and Capacitance Analysis

- Surge Comparison Test

- Partial Discharge Analysis

- Winding Circuit Analysis

- High-Potential Withstand

- Stator Wedge Tightness Assessment

- Natural Frequency Test

- ELCID

- RSO

- Partial Discharge Analysis

- Tan Delta and Capacitance Analysis

- Excitation Current Measurement

- Insulation Resistance and Polarization Index

- Turns Ratio

- Winding Resistance

- Oil filtration

Thanks to the wide array of tests that Intersel’s certified professionals are equipped and trained to perform, the predictive analysis is comprehensive with a higher-than-average degree of accuracy. And since we have experience with a wide variety of makes and models for motors, generators, and transformers, we are a viable alternative to multiple OEMs for predictive and preventive maintenance. This results in a more simplified, cost, and time-effective maintenance approach.

Intersel has the expertise and resources to not just predict the right time for maintenance but to perform the necessary maintenance tasks, overhauls, and repairs (if needed). Our maintenance capabilities include dismantling, cleaning, heating, varnishing, etc. For cleaning, we employ cryogenic cleaning (also called dry-ice blasting), which removes all surface contaminants without leaving any residue that may harm the equipment in the long run.

Benefits Of Outsourcing Predictive and Preventive Maintenance To Intersel

Most industrial sites have an in-house team of technicians and engineers responsible for routine equipment maintenance and ensuring that motors, generators, and other equipment remain in working order. They may even have the technology and training necessary for predictive maintenance of some or all equipment under their purview. Yet it’s still in the organization’s best interest to outsource predictive and preventive maintenance to companies like Intersel, and there are several reasons why:

- The depth of experience. Intersel’s certified professionals conduct more predictive and preventive maintenance tasks in a month than most in-house teams undertake in years. The wealth of experience Intersel’s technical and engineers bring to the table ensures streamlined maintenance that promises optimal results.

- Since they have worked in a wide variety of industries, each with its own operational, mechanical, and electrical challenges, they are capable of tackling a significantly wider variety of maintenance and repair challenges than an in-house team.

- Few in-house teams may have the equipment, training, and exposure on par with Intersel. Their knowledge and tools are, by necessity, limited to the operational needs of the organizations, whereas Intersel specializes in predictive and preventive maintenance (and repairs).

Maintenance contracts with Intersel can help you achieve a significant reduction in equipment failures and random shutdowns, which may cost far more than the equipment that triggered them. With our predictive maintenance measures, we can identify almost all potential points of failure and draw up an optimal preventive maintenance plan to eliminate them in due time. The formidable combination of decades of experience and cutting-edge technologies has placed our maintenance services in a class of their own.

Industries Serviced

DELIVERING INNOVATION

Cutting Edge Engineering Solutions Since 1986

We are focused on building a long-term, sustainable business.