Brochure

Download our document to see specific data of the service and how we work.

HOW CAN WE HELP YOU?

Talk or write to our experts to find your best solution.

On-site Rewinds

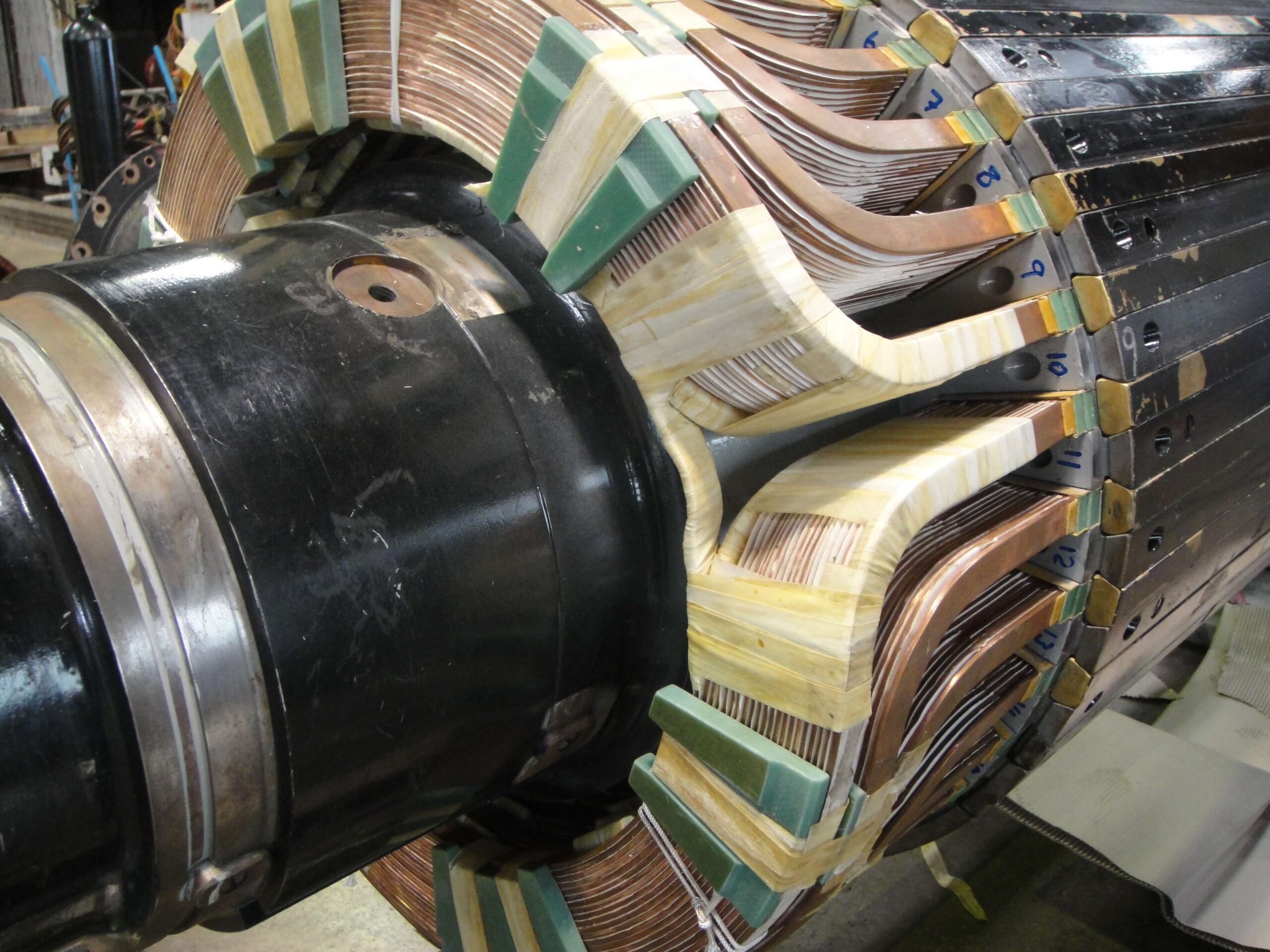

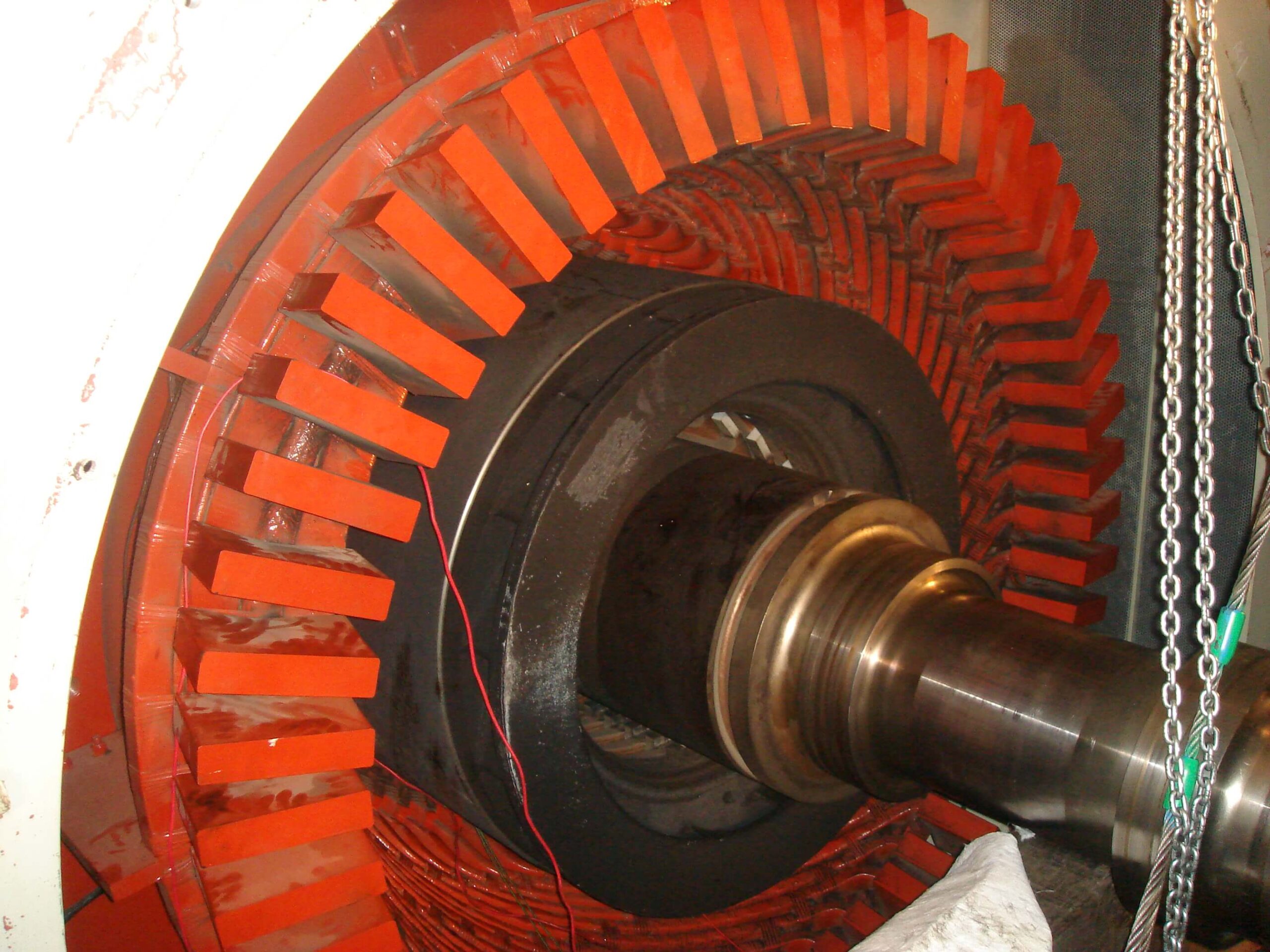

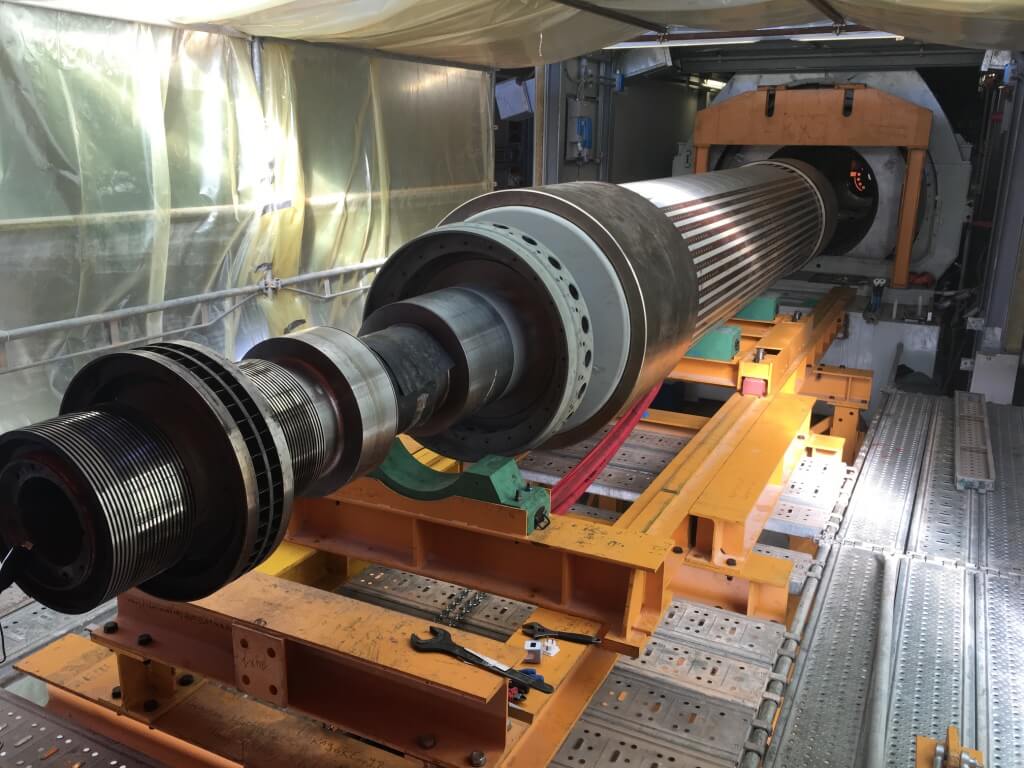

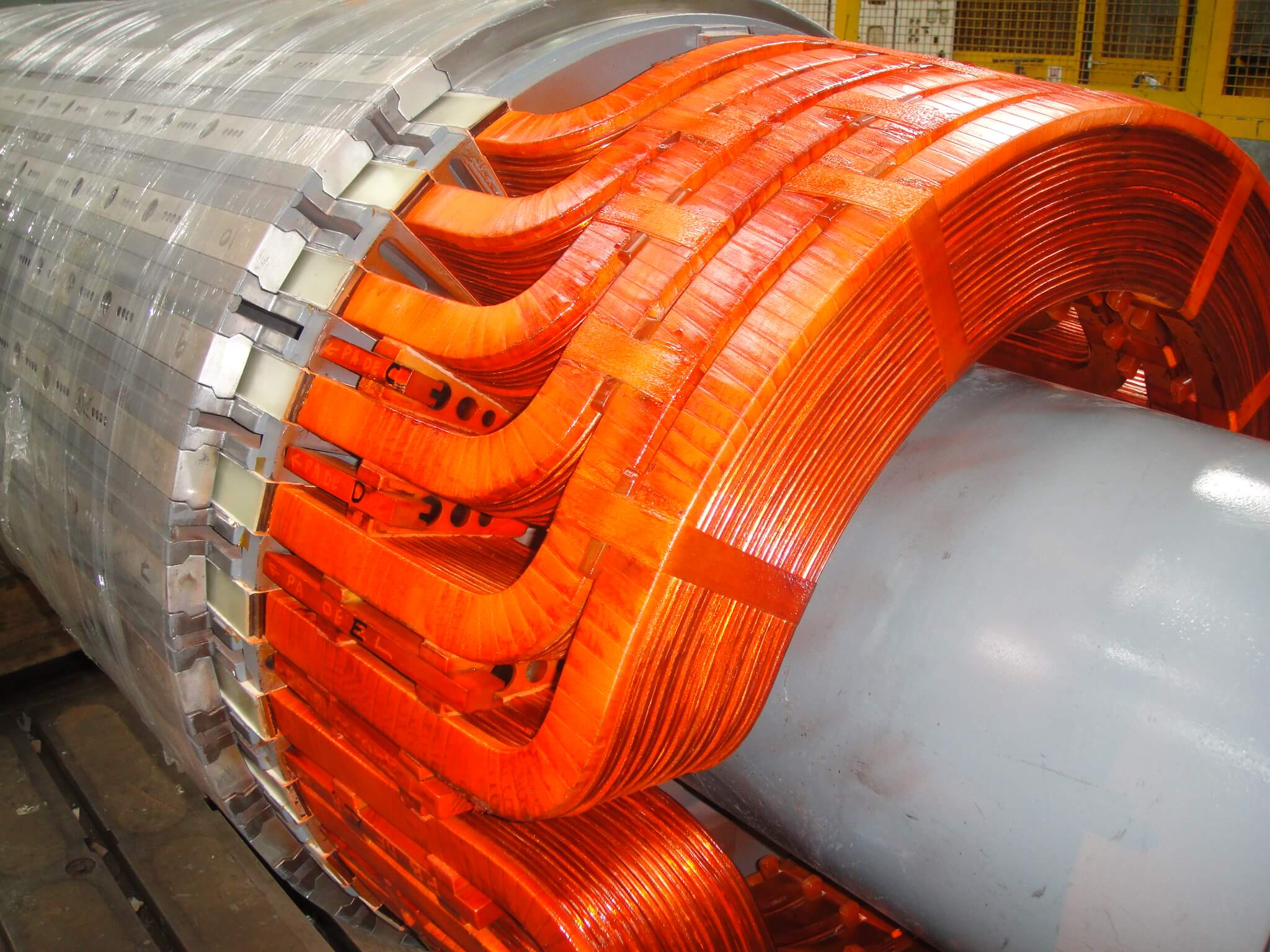

As the largest independent rotating equipment service provider in the Middle East, we have extensive experience in on-site motor and generator rewinds. Intersel’s certified field engineers and technicians have undertaken various on-site rewinding projects, which has equipped them with a rich skillset, allowing them to offer the right rewinding solution for unique and complex problems.

We offer:

- On-site rewinding of motors up to 18KV – Any makes (custom or standard design).

- On-site rewinding of both AC and DC motors.

- On-site rewinding of Turbo generators up to 200 MW – Any make, air-cooled

- Services to a wide array of industries and plants, including on-shore and off-shore oil rigs.

- On-site rewinding of marine generators.

Our on-site rewind services make us a faster and significantly more accessible OEM alternative for rewinds, repairs, and overhauling of motors and generators of all makes and most commercially available power configurations.

Every motor and generator rewinding project is different, mainly when undertaken on-site, where our field technicians and engineers don't have access to the full range of tools from our in-house facility, We supply the specialist engineers and our mobile workshop to site, thus delivering same high quality service in the field or in-house Still, there are certain processes and steps that are common in most jobs and should give you an idea of our approach and the comprehensiveness of our on-site rewinding solutions.

Inspection: We perform a comprehensive motor/generator winding inspection, life assessment and diagnose the corrective action best suited for our customer needs.

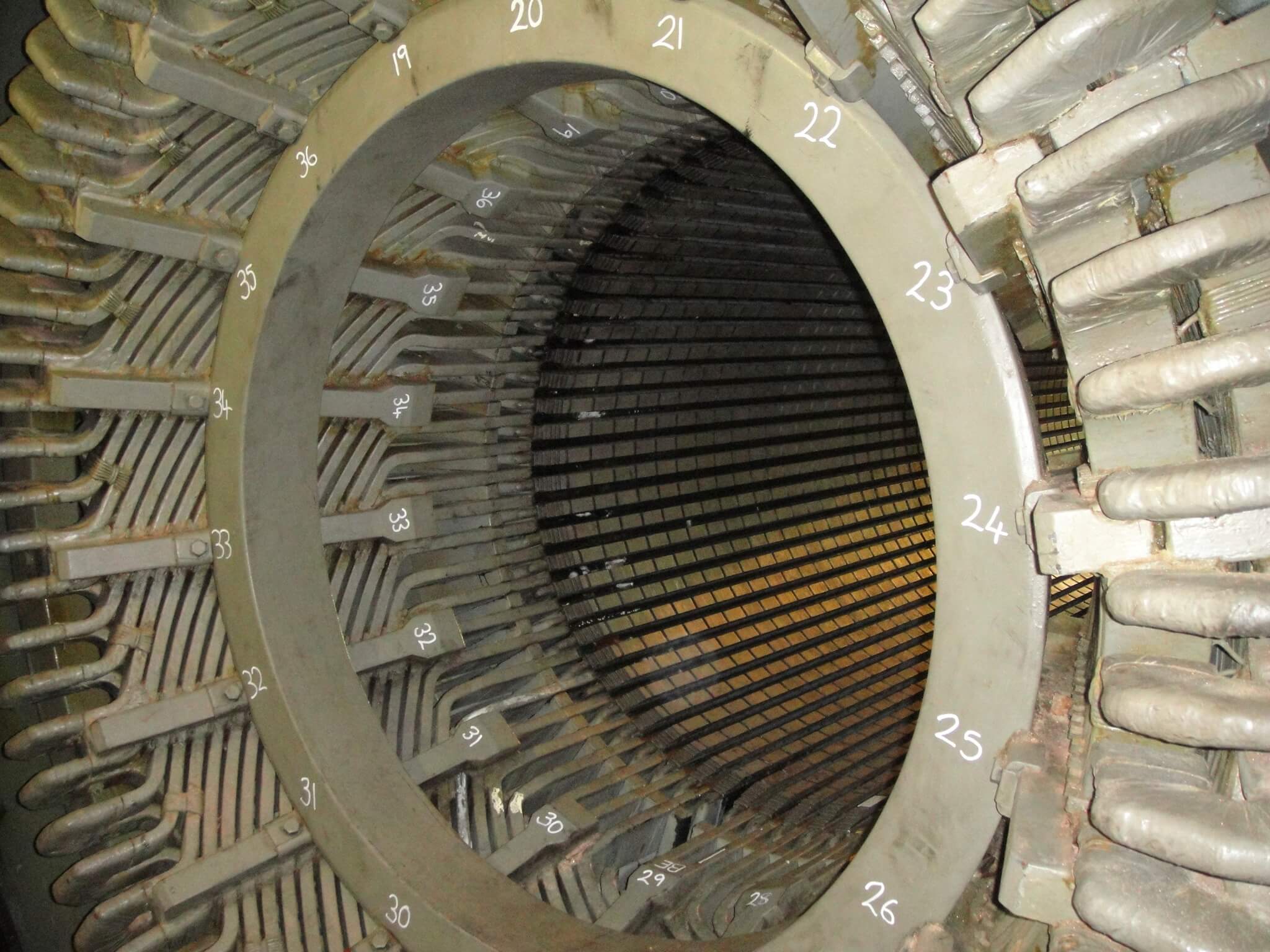

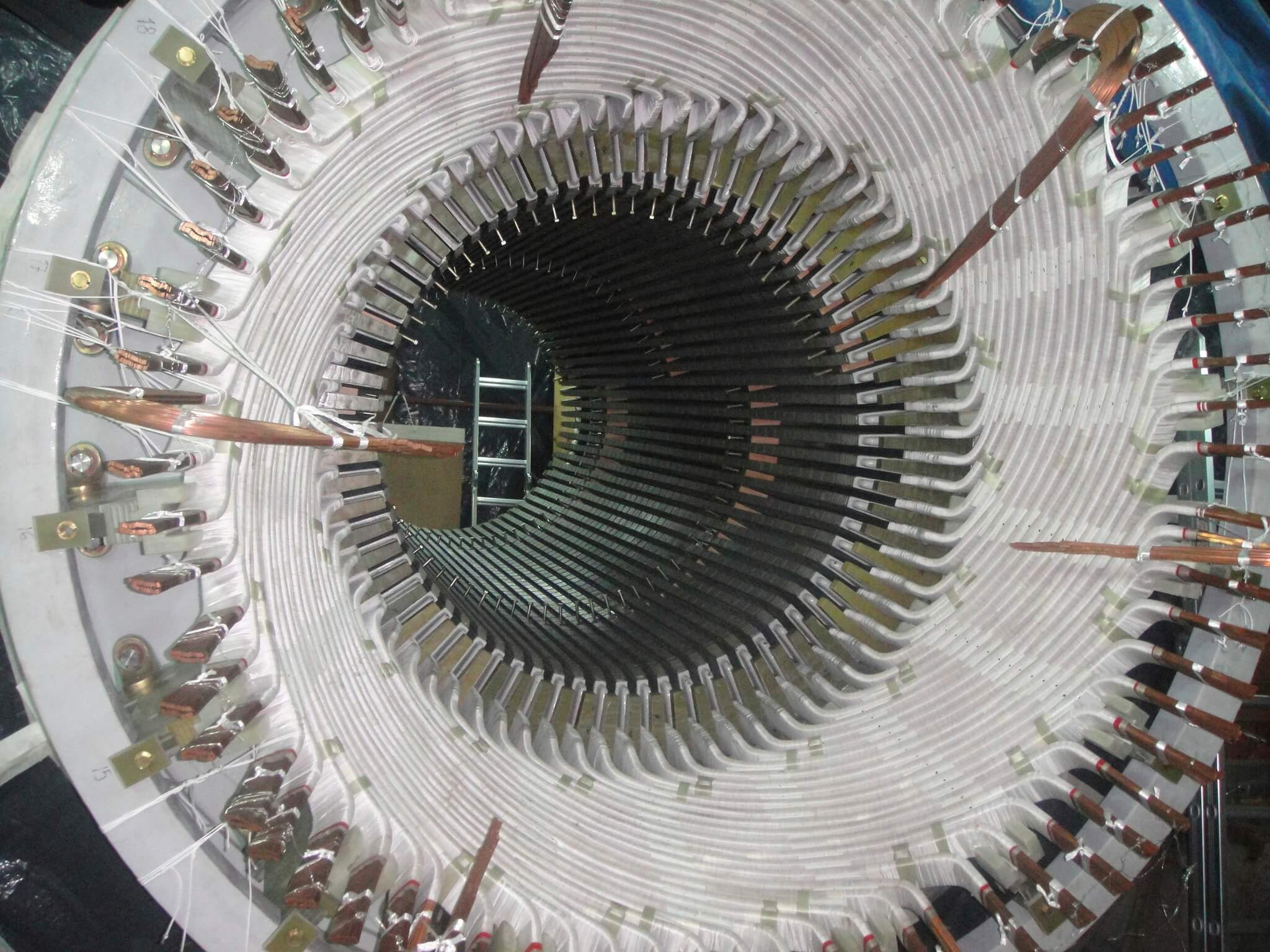

Existing Coil Removal and Cleaning: When necessary, stator bars and wedges are also removed for a thorough core inspection and cleaning.

Core Inspection and Repairs: Visual inspection, electromagnetic imperfection test (El-Cid) to identify problems in the core and recover any defects, from minor repair to complete core replacement.

Commissioning New Coils: Using our comprehensive coil data base, manufacture new coils, reverse engineer existing coil configuration, where possible, our engineering team can re-design to increase performance output and efficiency

Installation: From stator bars and wedges to coil installation, every step is taken with optimal longevity and performance in mind. Adjustments and, at certain points, replacements are made to ensure the rewinding results, guaranteeing the performance will meet or exceed the original OEM performance curve.

Inspection: Insulation testing is performed (usually at higher than operational levels) to ensure that it can survive potential surges.

Additional tests can be performed on motors serving a specific purpose and vulnerable to more than just usual wear and tear (mechanical and electrical).

We offer on-site rewind services for small, medium, and large motors of all make and models. We have rewound motors with a standard build, following the best OEM and industry Standards. We've also undertaken the rewinding service projects for custom motors where we had to re-engineer the design to ensure optimal efficiency after rewinding. We also focus on the longevity of the motor’s life after rewinding, full life extension.

In many cases, replacing a motor is a smarter, more viable long-term option than rewinding, but there are a lot of cases, especially involving obsolete, long lead times for new machines, high-powered, modified, or custom motors, where rewinding is the better choice. An on-site rewinding might result in minimal operational disruption compared to removing the motor from the premises.

When there are clear signs of deterioration in the motor and insulation resistance (identified from frequent shorts or a resistance test), that's when you have to make a choice regarding replacement or rewinding. If you choose to rewind, you have to analyze whether the motor can and should be removed from its current installation place so it can go through the rewinding process in one of our state-of-the-art facilities. If that’s not a viable option and the motor has to be rewound on the spot, we can dispatch our experts, along with our fully equipped mobile workshop, and carry out partial repair/rewind or complete turn key operation including full rewind and overhaul at site.

Intersel’s certified professionals have undertaken various generator rewinding projects since the company’s first foray into in situ generator repairs and have tackled a healthy collection of unique challenges and problems.

The most complex projects undertaken were on marine generators, on-shore, off-shore. These motors and generators can be installed in relatively small spaces surrounded by other equipment that’s difficult or impossible to remove in most cases, which makes dismantling a stator unit extremely challenging.

Still, we succeeded in all of the on-site motor/ generator rewinding projects we have undertaken so far, which is a solid endorsement of the capabilities and problem-solving skills of our on-site rewinding technicians and field engineers.

Past Projects

One major on-site rewinding project that our team undertook was the rewinding of a 93,750 kVA Ansaldo generator.

Industries Serviced

DELIVERING INNOVATION

Cutting Edge Engineering Solutions Since 1986

We are focused on building a long-term, sustainable business.