Fabrication and Re-manufacturing

Electric Motor Rewind And Overhaul Services

- Home

- Services

- Mechanical Services

- Fabrication and Re-manufacturing

Brochure

Download our document to see specific data of the service and how we work.

HOW CAN WE HELP YOU?

Talk or write to our experts to find your best solution.

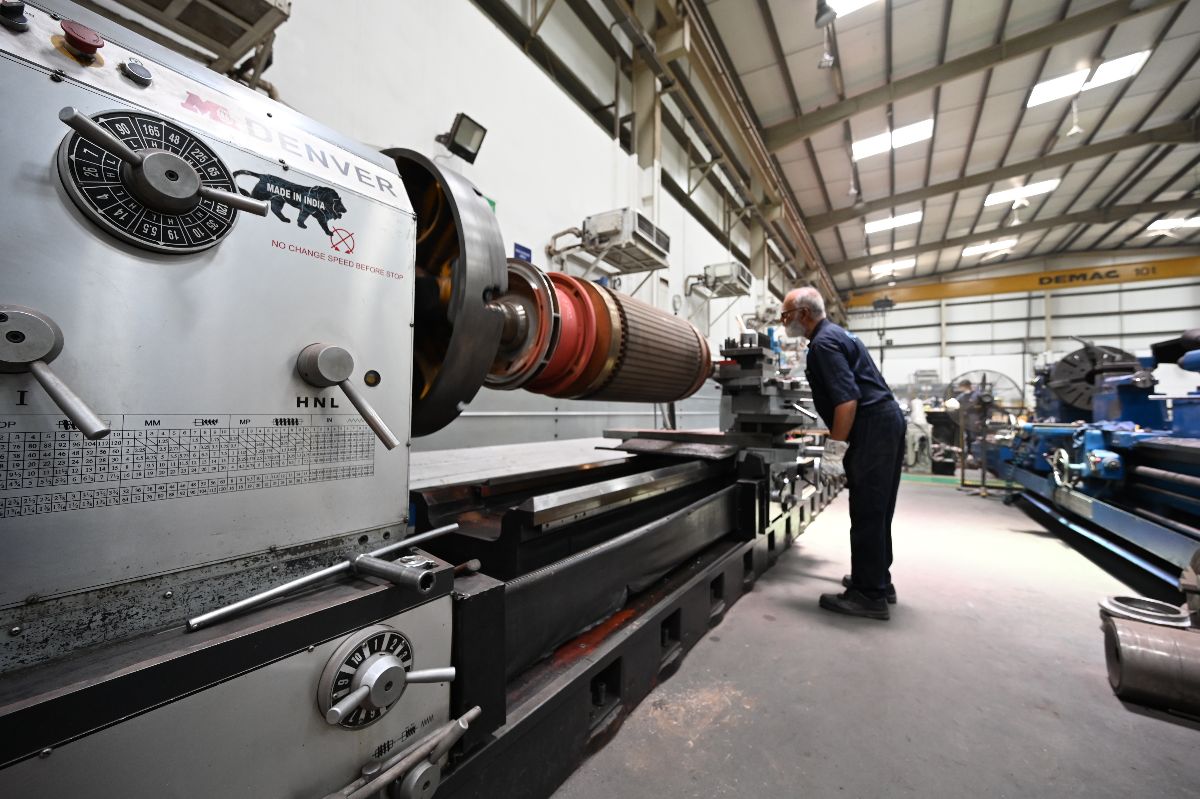

Intersel Fabrication Services

Intersel has been offering comprehensive rotating equipment services to the Gulf region since 1986, and fabrication has always been a crucial part of our service portfolio. Our state-of-the-art, 9,568-square-meter workshop is equipped with cutting-edge fabrication tools, and our engineers and technicians with decades of collective experience allow us to offer unparalleled fabrication services to clients from multiple industries. From stand-alone jobs to time-sensitive overhaul or repair-related fabrications, we are equipped to cater to all fabrication needs our clients might have.

Our industry-specific fabrication expertise includes (but is not limited to):

- Pipes, valves, fittings, vessels, oil and gas separators, valves, etc., for the oil and gas industry. Our extensive experience with the fluid mechanics of upstream, mid-stream, and downstream operations, along with the knowledge of mechanical integrity and compliance requirements for components and equipment to be fabricated allows us to cater to almost all specialized fabrication needs of our oil and gas clients.

- From structural integrity and dimensional accuracy needs of wind farm fabrications to the temperature resilience and abrasion-resistant material requirements of thermal power plant fabrications, we are equipped for almost all fabrication jobs our power industry clients might require. We also fabricate specific parts like coal nozzles and tips, pulverizer components, etc.

- When it comes to water and wastewater treatment, our fabrication capabilities include everything from working with corrosion-resistant metals to fabricating components and equipment for standardized and specialized wastewater solutions. This includes vessels, aeration systems, and components for filtration and treatment systems.

- We cater to the fabrication needs of our metal industry clients that either do not have the requisite in-house capabilities (tools or human resources) or outsource the tasks for better resource management.

- We are capable of fabricating components or parts of cement silos, cyclones, conveyors, coolers, and kilns, among others. Our metallurgical knowledge allows us to fabricate with alloys that may offer significantly higher wear and abrasion resistance than standard steel products, increasing their life.

- Intersel is equipped to fabricate pressure vessels, columns, dust collectors, air heaters/coolers, and tubes (among other things). We understand the corrosion-resistance needs of the petrochemical industry and the chemical properties of liquids (and gases) our fabricated components are expected to be in contact with, which allows us to fabricate for optimal longevity and safety.

- Our offshore fabrication capabilities are highly customized to the needs of the vessel we are producing components or equipment for. From fabrications specific to rotating equipment to tanks and other components onboard the vessel, we can fabricate almost all custom and standard metal parts/equipment for our marine industry clients.

- We offer fabrication services to pharmaceutical operations and food and beverage companies that adhere to their strict compliance codes. Our engineers are also well-versed in fabricating parts and equipment for textile processes like weaving, dyeing, stitching, etc.

In addition to these industry-specific fabrication needs, Intersel is equipped to cater to the common fabrication needs of all industries, including stairs, platforms, trays, exhausts, etc. Our mobile workshops allow us to take our fabrication capabilities far outside our workshop, and we offer field fabrication services (for certain jobs) while retaining the same quality standards characteristic of our work-shop-based manufacturing. We are an ISO 9001-certified company and adhere to the best fabrication practices and highest quality standards in every fabrication job we undertake.

Intersel Remanufacturing Services

At Intersel, we are committed to assisting our clients in generating maximum returns on their rotating equipment investments. This includes service and predictive maintenance aimed to prolong the equipment’s life by remanufacturing them to an “as-new” state. In some cases, we are able to enhance the operational quality and output of equipment by making the right modifications during the remanufacturing process.

The extent of remanufacturing depends upon the condition of the equipment at hand. For some equipment, partial remanufacturing is enough to restore it to the requisite operational configuration, while for others, comprehensive remanufacturing is required. The time, effort, and resources dedicated to remanufacturing are also proportional to the sophistication of the rotating equipment, which is radically different for exhaust fans and generators. However, the typical process has five stages:

- Disassembly of the equipment by certified technicians who ensure minimal damage to the individual components.

- A thorough assessment of the individual components and their structural integrity.

- A component-wise replacement/remanufacturing plan based on part availability, cost, and level of deterioration. Our reverse engineering capabilities allow us to remanufacture obsolete/legacy components.

- Replacements are arranged, and remanufacturing of individual components is performed following OEM design, reverse-engineered design, or modified design if the remanufactured rotating equipment is required to have different performance characteristics compared to the original design.

- Reassembling the remanufactured or replaced components.

- Rigorous equipment testing for desired configuration and specifications.

Our remanufacturing services allow our clients to keep using legacy or custom equipment well beyond their original life.

Industries Serviced

DELIVERING INNOVATION

Cutting Edge Engineering Solutions Since 1986

We are focused on building a long-term, sustainable business.