Welding and Metal Spraying

Electric Motor Rewind And Overhaul Services

- Home

- Services

- Mechanical Services

- Welding and Metal Spraying

Brochure

Download our document to see specific data of the service and how we work.

HOW CAN WE HELP YOU?

Talk or write to our experts to find your best solution.

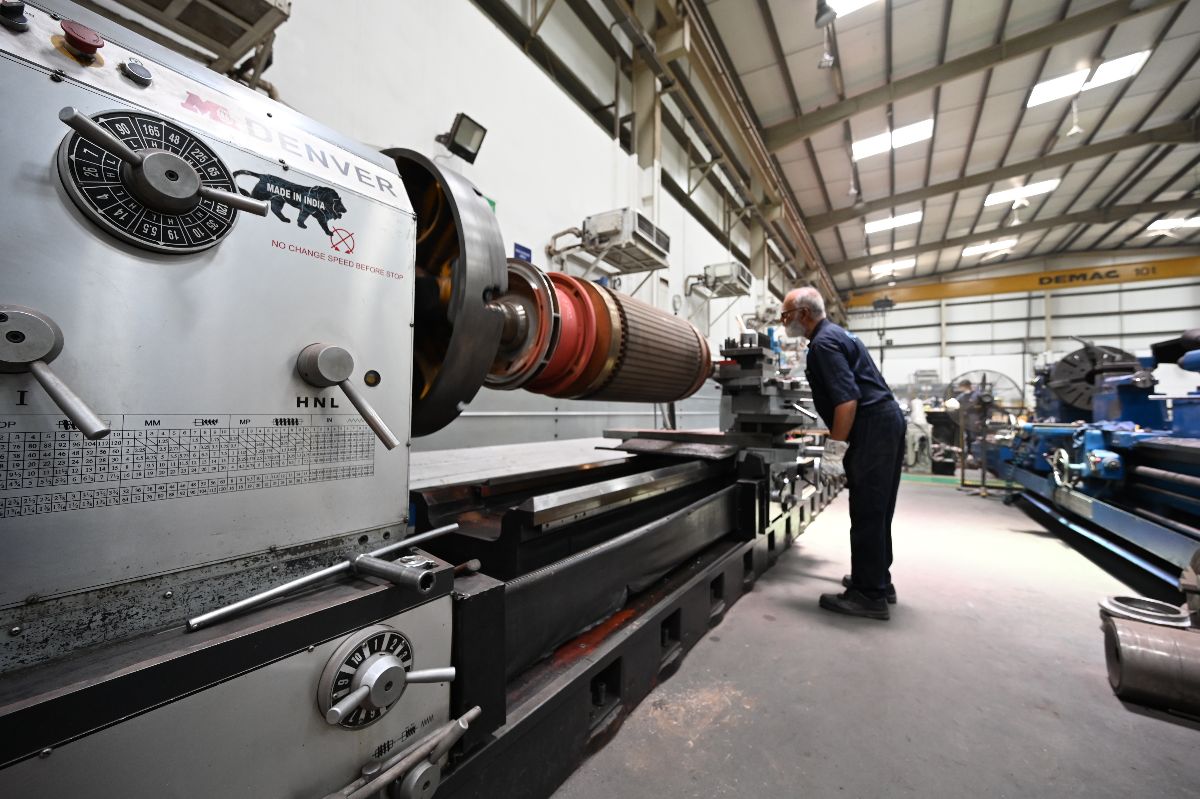

Intersel Welding Services

Intersel offers an extensive range of field and in-shop welding services. Our mobile welding plants are capable of meeting most on-site welding requirements for rotating equipment, and our certified and experienced welder maintains the same exceptional welding quality, whether on-site or in the Intersel workshop. Our welding certifications complement the extensive range of expertise our team is equipped to offer.

Our repair welding expertise augments our field and in-shop repair services in jobs where removal of complete equipment or on-site dismantling of pumps or generators (for removing vanes or blades), repair welding offers a practical intermediary solution that’s less time-intensive and may sustain the equipment till the next planned shutdown. Our welders and engineers are well-versed in the relative strengths of various filler metals, cracking sensitivities (base or filler metal), and other challenges associated with repair welding in various industries and environmental conditions and are capable of offering an optimal welding strategy.

Intersel’s certified welders are also experienced in fabrication welding.

Our welding expertise includes (but is not limited to):

- A comprehensive range of welding procedures, from precleaning, preheating, and environmental control to maintaining requisite cooling rates and heat treatment after welding.

- Working with a wide range of filler materials used in a variety of welding techniques.

- Experience with a wide range of metals, including cast iron, stainless steel, low-alloy steels, titanium alloys, nickel and cobalt alloy sheets, etc.

- Industry-specific welding needs and challenges. From the choice of filler material to unique environment-driven contamination risk, each industry has its own welding challenges and corresponding best practices, which Intersel’s expert welders are equipped to navigate.

- Weld overlay and cladding.

The last step of every welding job we undertake is a thorough inspection and analysis following international best practices and the repair/fabrication standards our clients follow.

Types Of Welding Services We Offer

Intersel’s fully equipped workshop and mobile welding plants cover a comprehensive variety of welding services.

- MIG Welding

- TIG Welding

- Arc Welding

- Gas Welding

- Laser Welding

- Orbital Welding

Intersel Metal Spraying Services

Intersel’s technicians and engineers have decades of experience repairing and servicing rotating equipment, and our metal spraying capabilities have always been an important component of these services. Metal spraying, also called thermal spraying, is the process of blasting molten coating material onto a component/equipment surface to achieve desired characteristics. These include:

Resistance To Corrosion: A base metal susceptible to corrosion due to its inherent chemical properties or environmental factors can be rendered adequately corrosion-resistant when coated with the right metal/alloy.

A Higher Degree Of Wear Resistance: From mechanical wear and tear to harsh environmental degradation, metal spraying can provide rotating equipment or individual parts modest protection against various destructive elements.

Protection Against Oxidation: A specific coating process called Chemical Vapor Deposition (CVD) is specifically employed for protecting gas turbines against oxidation and corrosion.

Restoration/Reclamation: Metal spraying and coating can assist in surface restoration and partial component reclamation if there are no structural flaws or insidious mechanical weaknesses. Metal spraying can also be used to achieve the desired thickness level to match the original dimensions.

Intersel has the equipment and certified technicians experienced in multiple metal spraying techniques, including electric arc, use of combustion powder and wire, and High-Velocity Oxygen Fuel (HVOF) spraying.

The Intersel Advantage

Intersel’s decades of experience in metal spraying techniques and top-of-the-line equipment allows it to offer unparalleled quality to its clients when it comes to metal spraying.

- Identifying the perfect coating material based on clients’ needs. Different environmental factors, wear-and-tear, base material, exposure to corrosive agents, etc., influence the choice of metal spray coatings/alloys.

- Determining the optimal coating thickness based on the operational requirement and metal spraying goals the client is aiming to achieve.

- Choosing the right metal spraying technique for the client’s needs.

- Rapid turn-around time facilitated by our expertise and use of the latest tools and technologies.

Industries Serviced

DELIVERING INNOVATION

Cutting Edge Engineering Solutions Since 1986

We are focused on building a long-term, sustainable business.