Design and Reverse Engineering

Electric Motor Rewind And Overhaul Services

- Home

- Services

- Mechanical Services

- Design and Reverse Engineering

Brochure

Download our document to see specific data of the service and how we work.

HOW CAN WE HELP YOU?

Talk or write to our experts to find your best solution.

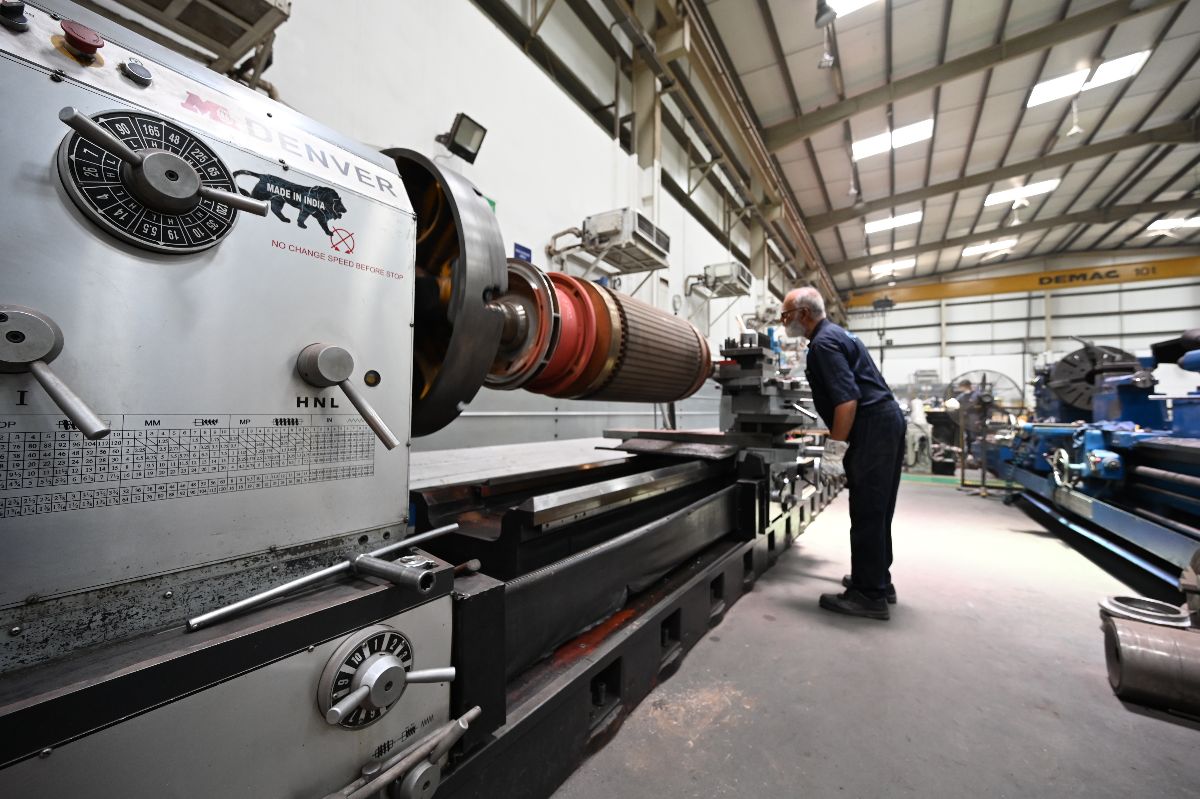

As the largest independent rotating equipment service provider in the Middle East, Intersel has over three-and-a-half-decade experience working with generators, motors, fans, pumps, and other rotating equipment of various makes, models, and mechanical designs. This experience, our OEM partnerships (with access to documents and training), and design knowledge and skill accumulated over the years allow us to offer our clients unmatched design and redesign services.

Our mechanical design services include (but are not limited to):

- Design of individual components.

- Complete rotating equipment design for original or modified performance specs.

- Drop-in replacement motor (and other rotating equipment) designs.

- Core, winding, support, and insulation design.

- Documentation (Datasheets, component assembly drawing, bill of materials, etc.).

- Compliance with international safety and design standards (and any additional compliance requirement the client might have).

- Component/equipment design to meet specific operational requirements.

Our redesign and re-engineering services are centered around improvement and optimization. Through partial or complete redesigning/re-engineering, we can help our clients achieve various equipment improvement goals, including:

- Generator and motor uprating.

- Re-rating to meet new production/operational requirements.

- Frame or housing redesign to accommodate changes in the installation site (or for new installation sites).

- Upgrading/replacing materials for a longer operational life.

- Design improvements based on equipment wear and tear assessment.

- Repurposing rotating equipment for different environments and loads.

- Improving energy efficiency.

We also redesign equipment to match the original OEM performance specifications, where repairing is not an option, and OEM replacements are time-intensive.

Our diverse portfolio of clients from various industries, including oil and gas, food, and cement, each with its own operational requirements, compliance codes, HSE and quality standards, and unique environmental considerations, has enhanced our design capabilities. The excellence of our design and redesign services stems from our latest design tools, in-depth understanding of cutting-edge design practices, use of simulations, comprehensive testing, and a feedback system to ensure that the final design perfectly matches clients’ requirements and vision.

Legacy and obsolete rotating equipment with incomplete or missing OEM designs can be challenging to repair or replace, especially if the OEM doesn't offer technical support for the equipment in any capacity and current equivalents are not a feasible match, even with necessary adjustments.

Our reverse engineering capabilities allow us to offer optimal solutions to our clients in such cases. Our top-of-the-line scanning tools augmented by our comprehensive testing capabilities allow us to reverse engineer almost any rotating equipment design, even if the sample equipment is partially damaged. And we offer more than just reverse-engineered replacement for obsolete equipment. We offer detailed designs and other documents to ensure future replacements and repairs are not as time and resource-intensive and don't have to go through the same cycle.

Intersel’s reverse engineering capabilities include:

- Dimensional accuracy: Our scanning equipment and testing capabilities allow us to reverse engineer the mechanical design for any rotating equipment with exceptional dimensional accuracy. We account for wear and tear, so our reverse engineered designs match the original OEM versions (at the time of manufacturing), which also results in a restoration of original performance specifications.

- Comprehensive Range: From a wide range of AC/DC motors to brush turbo generators of various makes and models, we can reverse engineer a comprehensive range of rotating equipment. Motors, generators, and fans/blowers are our forte, but we can also reverse engineer other rotating equipment (pumps, gearboxes, etc.).

- On-Site Scanning: Our mobile workshops and on-site scanning and testing capabilities allow us to gather the necessary data (physical dimensions, process variables, performance data, etc.) directly from the operational site. This is ideal for equipment that has to be reverse engineered while still in service (no downtime) or equipment that may be damaged further if removed from the site.

- Improvements: We combine our reverse engineering services with our redesigning capabilities to enhance/improve upon legacy designs. New insulation technologies, different coatings, and using upgraded materials are just some of the changes we can make in the legacy design to ensure that the re-engineered product is more efficient, requires less frequent maintenance, and has better performance specifications (if needed).

The decades of experience our engineers and design team collectively offer, combined with the use of the latest technologies and following the best industry practices, ensures exceptional quality and reduced lead times. This makes our reverse-engineering services a more optimal choice for many of our clients, even when OEM offers support for the equipment.

Industries Serviced

DELIVERING INNOVATION

Cutting Edge Engineering Solutions Since 1986

We are focused on building a long-term, sustainable business.