Electric Motors & Generators Repair

Electric Motor Rewind And Overhaul Services

- Home

- Services

- Workshop Repairs

- Electric Motors & Generators Repair

Brochure

Download our document to see specific data of the service and how we work.

HOW CAN WE HELP YOU?

Talk or write to our experts to find your best solution.

Electric Motors & Generators Repair

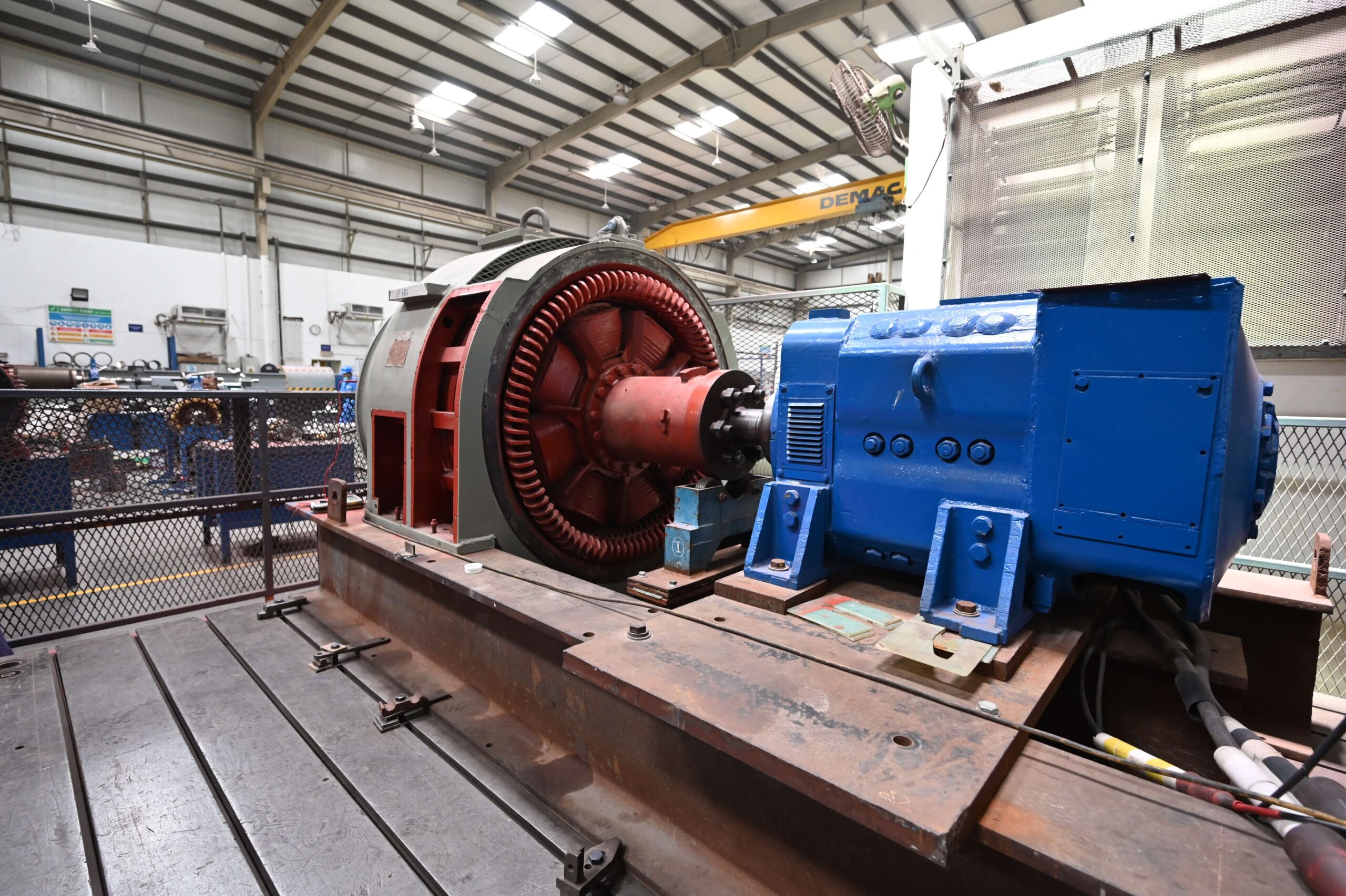

Intersel has a top-of-the-line, fully-equipped workshop where our certified technicians and experienced engineers undertake a wide variety of electric motors and generator repairs. From smaller motors (low voltage) with fractional horsepower to medium voltage motors (maximum voltage – 13.8 kV) with a power rating up to 6,000 horsepower, we can repair most synchronous and asynchronous motors used in a variety of industries. For generators, our largest in-house repair project so far has been a complete rotor and stator rewinding of a 39,540 kVA Brush Turbo generator (3600 rpm). But we have the capacity to repair larger generators.

We repair a wide variety of electric motors, including:

- AC Motors (Both Induction and synchronous)

- DC Motors (Permanent magnet, series, and shunt)

- EX Motors (Most standard protection types)

- VFD Motors

- Compound Motors

- Special purpose motors

In addition to standard makes and models with OEM manuals and designs available, we also have extensive experience repairing obsolete and custom motors with no or incomplete design documents. We are capable of reverse engineering the mechanical and electrical design to ensure that the repaired motor performs as close to the original specifications as practically possible.

Workshop Highlights

Our in-shop repair capabilities rely quite heavily on the equipment we have at our disposal. It affects everything, from the magnitude to the overall scope of the electric motors and generator repair we can undertake.

- Six overhead cranes (Demag) 10 ton x 5 / 25 ton / 30 ton / 50 ton with total lifting capacity of 155 tons

- Dynamic Balancing Machine (Schenck Avery), which can handle up to 12-ton rotors, 2.1 m x 6 m (diameter x length), and an RPM range of 210 – 1680.

- Dynamic Balancing Machine (Abro), which can handle up to 30-ton rotors,

- One high power and one medium power motor testing panel (Phenix Technologies)

- Hi-Pot Test Set (PJ Electronics) – Maximum Output Voltage 50 kV

- DC Insulation Tester (Hipotronics) – 80 kV

- Thermographic Camera – Flir P620

- VB8 Four-Channel Vibration Analysis System (Commtest)

- Laser Alignment System

The workshop also includes a number of smaller testing and repair equipment that’s used for both in-shop and on-site repairs. Partial discharge, winding circuit, vibration spectrum, and acoustic emission analyzers are just some of the other equipment used for in-shop electric motors and generator repairs.

The Intersel Advantage

Intersel is the largest independent rotating equipment service provider in the Middle East. We have been providing electric motors and generator repair services since our inception in 1986, when we started out as a small repair facility. This line of service is connected directly to our roots, and as we evolved over the decades, we have also grown our in-shop repair capabilities.

A few reasons why we are the premier electric motors and generator repair company in the region are:

- We cater to a wide array of industries. From power generation and energy to the maritime industry, we help a variety of businesses with their rotary equipment repair needs. This has exposed us to an impressive variety of motors and generators, and this rich experience has enhanced our repair capabilities above and beyond our peers.

- Our repair process is augmented with advanced testing capabilities. Despite having a team of experienced and certified professionals capable of offering creative repair solutions, we rely heavily on advanced testing. So our “as-new” repair claims are backed by tangible numbers and data, which offers our clients more peace of mind and confidence.

- Our in-shop repair facility is equipped with state-of-the-art tools, and our team of technicians and engineers stay updated on new and best repair/analysis practices and techniques. The two strengths complement each other, and the result is efficient and high-quality repair jobs for motors and generators.

- We offer turn-key repair services to clients that need them. This includes removing, dismantling (if necessary), packing, transporting, repairing, and reinstalling motors and generators in the clients’ facilities. Our experts are also able to provide relevant consultation to the clients regarding the best course of action, i.e., repair or replacement.

We offer exceptional turnaround times to our clients, especially for time-sensitive repairs where the absence of the motor or generator has halted operations. However, our ultimate goal is excellent repairs.

Industries Serviced

DELIVERING INNOVATION

Cutting Edge Engineering Solutions Since 1986

We are focused on building a long-term, sustainable business.