Comprehensive Testing

Electric Motor Rewind And Overhaul Services

- Home

- Services

- Workshop Repairs

- Comprehensive Testing

Brochure

Download our document to see specific data of the service and how we work.

HOW CAN WE HELP YOU?

Talk or write to our experts to find your best solution.

Comprehensive Testing

As a rotating equipment services leader in the Middle East, Intersel’s comprehensive testing portfolio is extensive and competitively formidable. And are constantly adding to our testing portfolio as we aim to stay ahead of the curve when it comes to the evaluation and diagnostics of rotating equipment. This testing augments and strengthens our predictive maintenance, repairs, and overhauling services and is a core element of the excellence Intersel is known and trusted for.

Here is an overview of what our comprehensive testing involves:

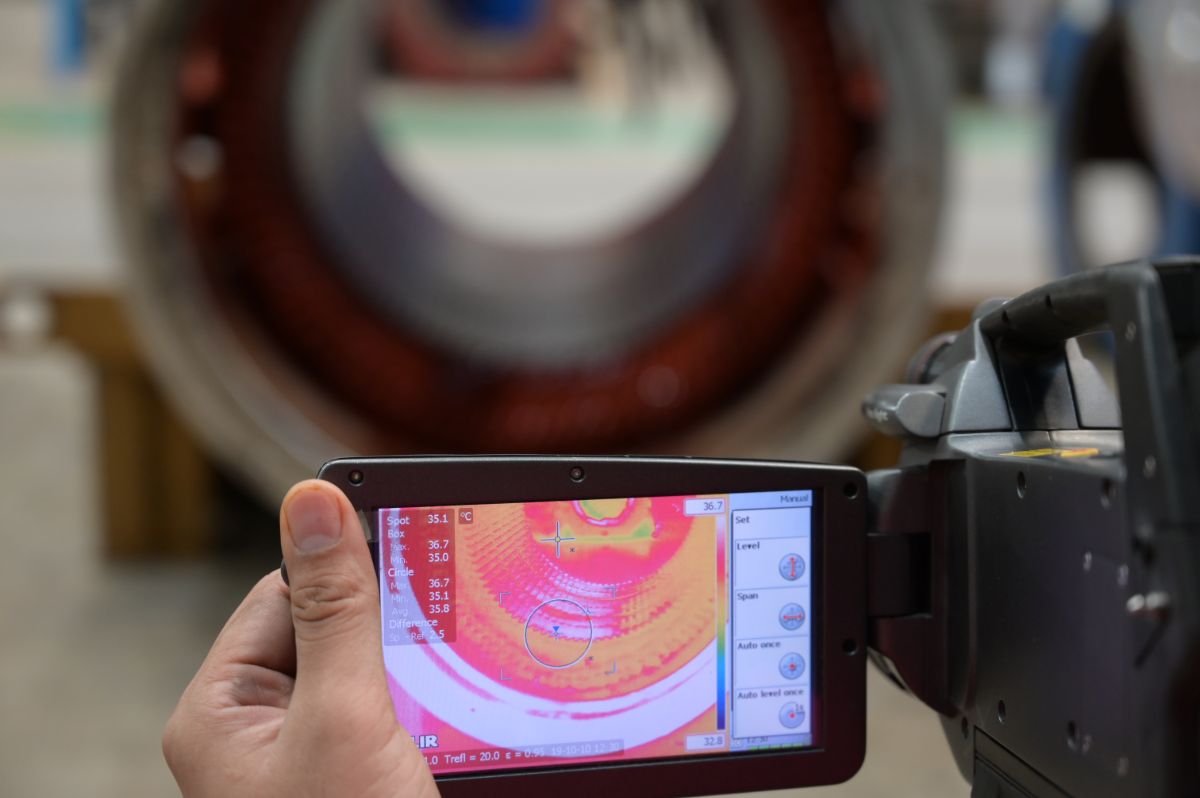

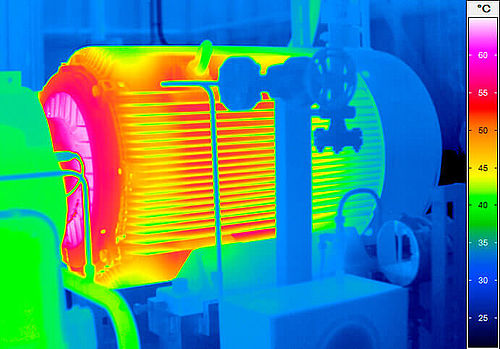

Thermography or infrared thermography is used to measure if and when rotating equipment like a generator or a motor is producing more heat than it should. This can offer important insights into the equipment's mechanical and electrical condition and help in identifying problems like worn bearings or cooling system issues.

Vibration spectrum analysis which dives deeper than the time domain vibration analysis, can help detect any abnormality in rotating equipment. This helps flag relatively small problems well before they can trigger an equipment failure.

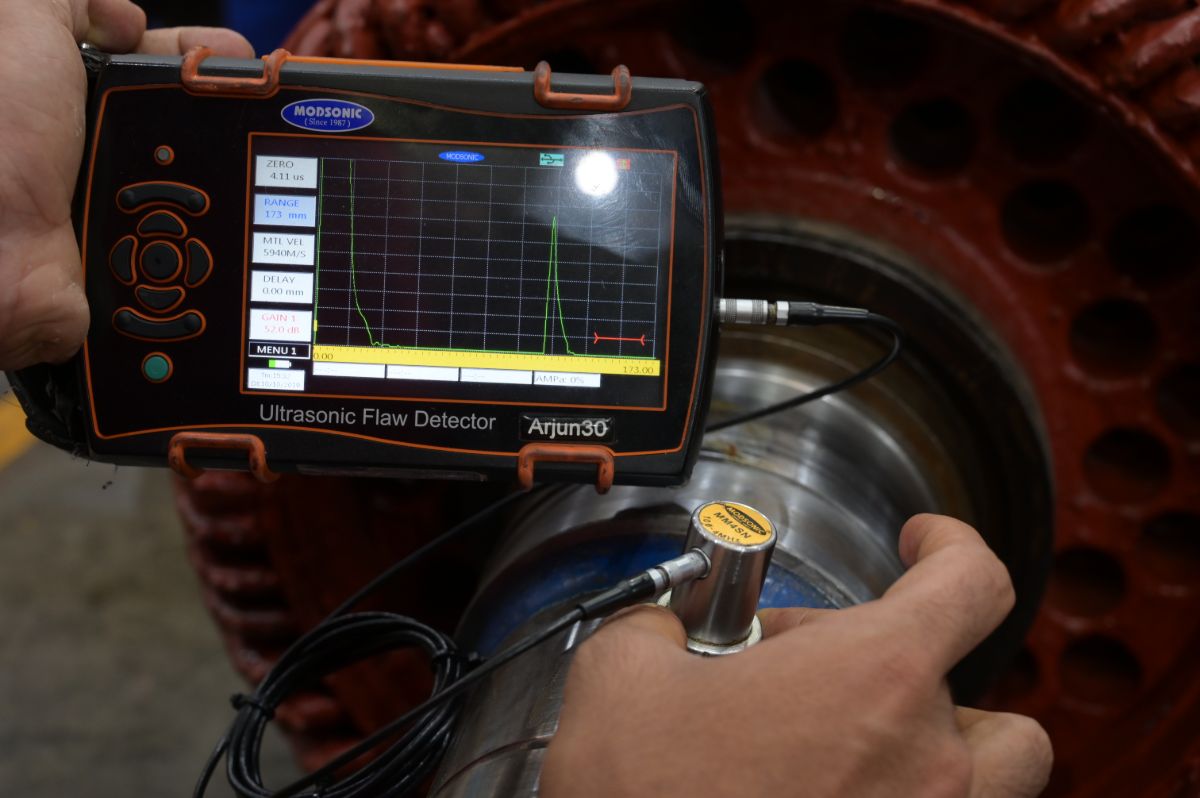

Acoustic emission analysis is an NDT (Non-Destructive Test) that helps us determine deformities in a structure which usually stems from high/abnormal mechanical stress. Ultrasonic testing, especially for motors, helps identify whether motor bearings are under or over-lubricated and may warn against potential bearing failure. Both of these tests rely upon sound.

Borescope inspection is a type of visual inspection that allows you to see hard-to-reach areas without disassembling/dismantling equipment. It can be used in generator inspection to identify mechanical flaws like a damaged coil or greasing in unwanted areas.

While not as efficient as most modern testing techniques, growler testing can still be used to identify shorted, grounded, or open wiring. It can also be used to identify an open rotor bar.

The surge comparison test is an important rotating equipment test that is used to find insulation weaknesses in the winding of motors and generators above and beyond what other tests, like megger/megohm and hipot tests, might help you find. Surge comparison is ideal for turn-to-turn insulation testing, and it's often used in parallel to partial discharge tests.

Insulation breakdown is one of the leading causes of equipment failure, and partial discharges can (over time) lead to insulation flaws and damages. Partial discharge analysis can help identify potential points of failure so you can make informed maintenance/repair decisions on time. Partial discharge may occur from flaws in the stress grading treatment applied to the winding or conductor-insulator debonding (among other things) and may manifest as a corona.

The tan delta and capacitance test helps us analyze the ground wall insulation and identify problems like moisture content, voids, contamination, and aging. Its results are not as localized as partial discharge analysis but are still crucial for determining the overall state of the ground insulation.

This test employs magnetic particles – dry powder form or wet solutions (the size of the particles is radically different) to find flaws and cracks in the surface of ferromagnetic materials like steel or nickel. It’s a non-destructive test (NDT).

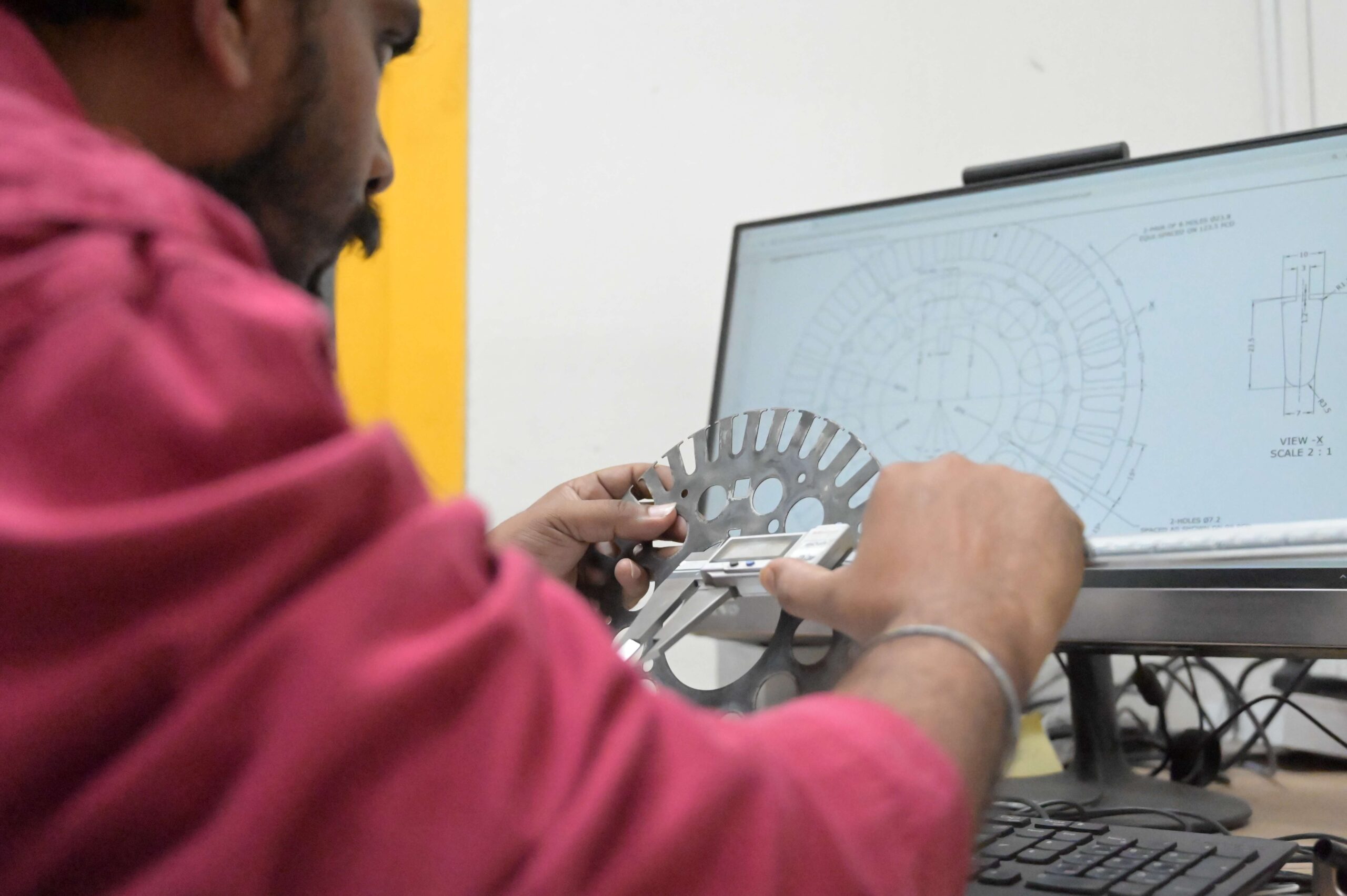

Winding circuit analysis is a set of tests that aim to predict and identify winding, rotor, and cable defects in rotary equipment (and transformer) using multiple electrical inputs – resistance, impedance, inductance, phase angle, and I/F response.

Rotating equipment like generators and motors have a specific vibration response between 95 and 100 Hz. If the stator coil has a resonant frequency similar to the overall structure, it may lead to a vibration imbalance, and eventually, mechanical failure. The winding is strengthened until there is a satisfactory frequency imbalance.

ELCID is used to check the integrity of the stator core lamination. Interlamination imperfections are identified before they can overheat and damage the core. The localized nature of this test, easy setup, and minimal excitation power requirement makes it a popular choice for detecting potential flaws in the generator core.

Inter-turn shorts, i.e., shorts between individual windings, might not be enough to cause a large-scale equipment failure by themselves, but these localized shorts can lead to more damaging winding failures. RSO is an easy way to detect and rectify these winding problems or at least set a more practical predictive maintenance date.

These tests and analyses are a reflection of our comprehensive testing capabilities both in-shop and on-site. This is also an endorsement of our predictive maintenance capabilities. In addition to the tests focused on rotating equipment, we also have extensive transformer testing capabilities.

Industries Serviced

DELIVERING INNOVATION

Cutting Edge Engineering Solutions Since 1986

We are focused on building a long-term, sustainable business.