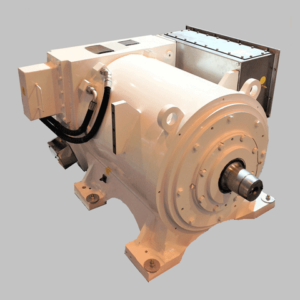

1300 HP AC Water Cooled Motor

Electric Motor Rewind And Overhaul Services

- Home

- Services

- Sales and Distribution

- AC/DC Drill Motors

- AC Water Cooled Motors

- 1300 HP AC Water Cooled Motor

Brochure

Download our document to see specific data of the service and how we work.

PROFILE.PDF

4M FIELD SERVICES.PDF

0.6M HOW CAN WE HELP YOU?

Talk or write to our experts to find your best solution.

1300 HP (858 KW) AC WATER COOLED MOTOR

5GEB1300W Series

Models

- 5GEB1300WH

Single shaft extension - 5GEB1300WV

Double ended shaft extension

Quick Facts

- 6-pole stator with “form-wound” windings

- Copper chromium alloy rotor bars

- Class H insulation, robotically taped, Mica-Kapton system

- Single or double shaft extensions, High strength 4130 alloy shaft on drive end

- Insulated bearing on non-drive end

- Stainless steel main terminal box is IP56 (Ex e) with bus bar connections for main cable terminations. Terminal box can be specified to be mounted on left “A” side or right “B” side of motor as viewed from non-drive end of motor. Available in standard, half (as shown above), or compact

- RTD and heater leads exit the lower window of the frame. The leads can either be terminated in an Ex e auxiliary box or routed to a remote auxiliary box

- Six (6) RTDs, 100 ohm platinum, two per phase embedded in stator slots

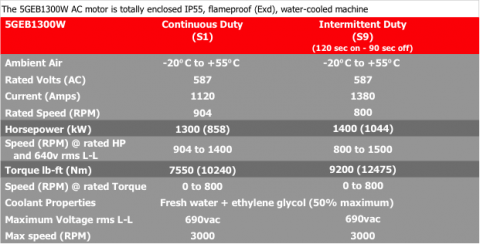

- Cooling System requires 33 gpm at maximum 38°C freshwater cooling (up to 50/50 freshwater/glycol mix), which is split between stator and rotor, 22GPM and 11 gpm respectively, 100psi maximum operating pressure.

- Ambient temperature 55°C

- Tape Heater, 200W total

- Motor enclosure: Ingress Protection (IP56)

- Certifications:

- IECEx, & ATEX Certified

- CSA [both US and Canada] (Optional)

- ABS Certification

- DNV (Optional)

Industries Serviced

DELIVERING INNOVATION

Cutting Edge Engineering Solutions Since 1986

We are focused on building a long-term, sustainable business.